CTP Digital image on flexo plate

CTP Digital image on flexo plate CTP laser for color label

CTP laser for color label CTF Digital inkjet film making

CTF Digital inkjet film making CTF 175 / 133 / 85 lpi dot

CTF 175 / 133 / 85 lpi dot CTS digital image on screen

CTS digital image on screen LaserBlack- black film enhancer

LaserBlack- black film enhancer @flexo liquid plate making

@flexo liquid plate making @flexo plate making machine

@flexo plate making machine Model: EZ (Easy type)

Model: EZ (Easy type) Model:A4/A3/A2

Model:A4/A3/A2 2436/3040/4050/4260

2436/3040/4050/4260 New automatic washout m/c

New automatic washout m/c Clean & wash after printing

Clean & wash after printing Stamp Making

Stamp Making Photopolymer plates

Photopolymer plates Letterpress plates

Letterpress plates Flexo plates (solvent wash)

Flexo plates (solvent wash) Water wash flexo plates

Water wash flexo plates Digital photopolymer plates

Digital photopolymer plates Liquid photopolymer resins

Liquid photopolymer resins For cup.can.tube.pad printing

For cup.can.tube.pad printing For block print

For block print Cushion Backs = F-Bak

Cushion Backs = F-Bak Double-side tapes for printing

Double-side tapes for printing In plant plate making

In plant plate making

View Big Picture

View Big Picture

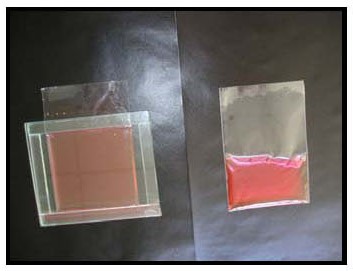

@StampBag System

A Contemporary Sachet Technology for Stamp Making

Water wash - Enviro green - Innovative

Quick x Easy x Economic x Time & Labor saving

(Only a double side exposure unit is required)

@StampBag is a completely new development for stamp making from an office stamp to mass production of fancy stamps. This innovation is experienced from 30 years of conventional liquid & solid photopolymer stamp making.

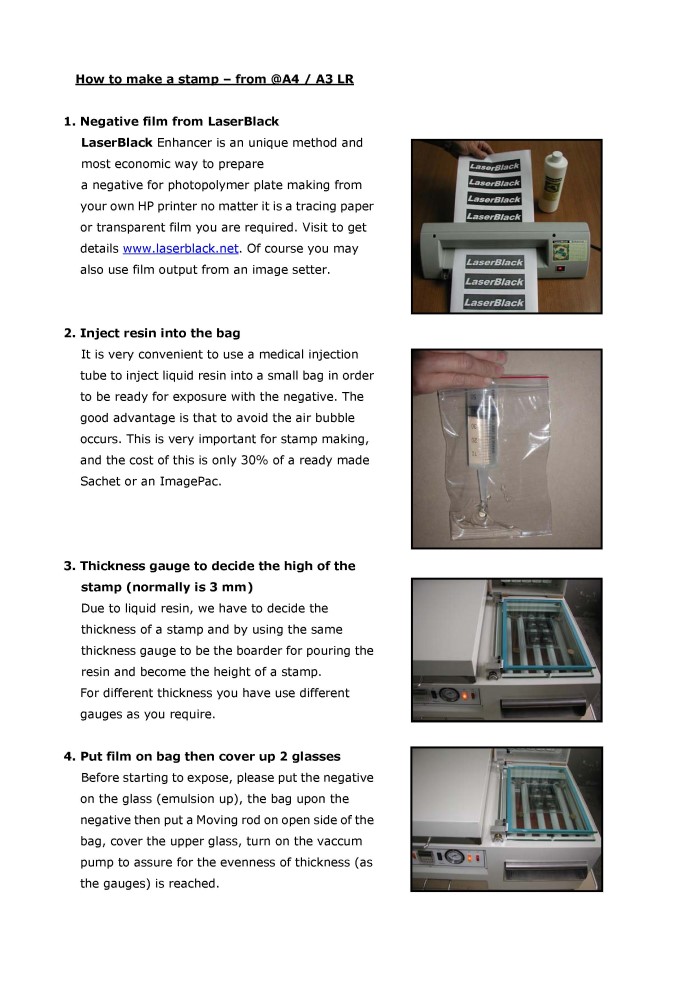

LaserBlack Enhancer is your image setter

LaserBlack Enhancer to make negative from your laser printer,

which is a perfect solution for water washout stamp making. Please visit www.laserblack.net for more information.

@StampBag is a faster exposure, with fine reproduction details, water washout, easy and rapid operation. for a 3mm stamp the exposure time is only 2 minutes in total, wide latitude, fine details, no bubbles, tolerance in + / - 0.03mm , you may make the bag from size A8 to A0 size, big size plate is good for corrugated printing

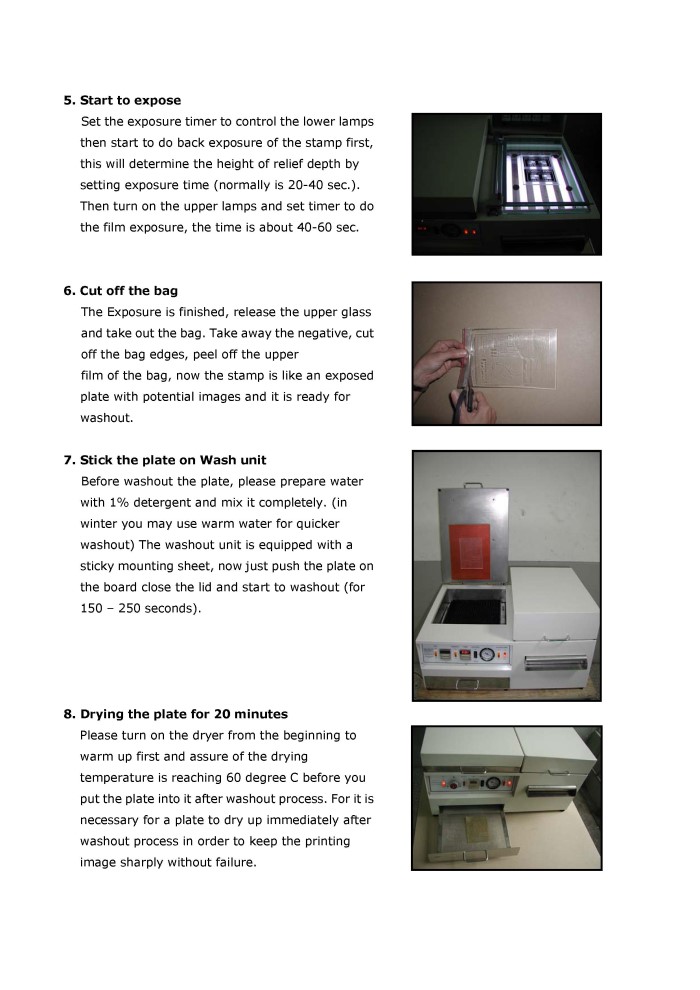

Water wash-out is the best advantage of @StampBag System, no solvent means less drying time, quick ready as well as saving cost for plate making and environmental green. Water washout time is only 2 minutes.

In less than 20 minutes, you can have a stamp made from your monitor including print out, LaserBlack enhancing as a negative film on tracing paper and stamp making by water wash. Remember that cost of tracing paper is as low as nothing.

@StampBag is an invention / patent of liquid photopolymer stamp making.

http://www.flexotech.com.tw/ch/DownShow.asp?ID=55

TO VIEW COMPLETE PROCESS PLEASE EMAIL TO flexotec@ms32.hinet.net

IN ORDER TO SEND FILE IN DETAILS FOR YOU.

|

FOR STAMPS

|

|

Exposure with Vacuum pump + Dryer

|

|

Water washout + Treatment

|

| Suitable: |

| 1.Liguid photopolymer stamp making. |

| 2.Liguid resin in bag stamp making |

| Model: |

| NEW @A4 LR ( Liguid Resin ) @A3LR |

| NEW @A4 FB ( Resin in Bag ) @A3FB |

|

@A4 (21 x 30 cm) For Stamps / Liguid Resin / bag |

|

@A4 LR @A3LR-for liquid resin @A4 FB @A3FB-for @FlexoBag |

|

MODEL

|

UNIT

|

MEASUREMENT(mm)

|

N/W

|

G/W |

WATT

|

|

@A4 LR

|

Exposing+Drying

+Washout +Treatment |

760 x 650 x 400 mm

|

56kg

|

90kg

|

1kw

|

|

@A4 FB

|

760 x 650 x 400 mm

|

56kg

|

90kg

|

1kw

|

|

|

@A3 LR

|

940 x 770 x 400 mm

|

85kg

|

125kg

|

1.2kw

|

|

|

@A3 FB

|

940 x 770 x 400 mm

|

85kg

|

125kg

|

1.2kw

|

F-90 photo resin

Liquidpolymer@matrix

@flexogroup is announcing a new product of F-90 liquid photopolymer resin which is good for casting / molding / casting industries and rubber stamp / plate making as a plate for matrix making. Low cost, water wash, easy operation and economic equipment capital investment are the merits. By only preparing a can of F-90, you can make hardness of 90 Shore A (32 Shore D) and heat resistance of 180 degree C to make any size mold or matrix plates you like in depth of 5mm.

Solid plate for matrix is getting less will disappear soon and the cost of it is higher and higher. By using liquid photopolymer the cost is only 30% of a solid photopolymer matrix plate. In addition, no more acid etching of metal plate in order to improve our environment green of no pollution. Due to new invention and innovation, from LaserBlack now you can have negative to make a plate quickly from your laser printer also due to @stampBag patented liquid photopolymer plate making new method, now it is very easy to make a plate in plant for molding, matrix or printing.

LaserBlack enhancer can make a negative by your own HP laser printer print on tracing paper or transparent film, go through our Enhancer then after drying it you will have a very black negative on hand in your plant for all of any plate exposure. www.laserblack.net

By an innovative concept of putting resin into a bag to pre-move the bubbles to save your processing time, @stampBag is a total new solution for you to make a plate from liquid photo resin quick, easy with clean hands. The equipment is available from A4 size to A3 and any bigger size as you wish for mass production.

Compacted 4 in 1 design table top plate making machine for liquid photopolymer matrix plate

Machine including: Exposure / washout / drying / anti-tack complete functions in one unit

Costs only 1/3 of photopolymer matrix plate. Product quality is perfect enough to replace.

Compacted 4 in 1 design table top plate making machine for liquid photopolymer matrix plate.

Machine including: Exposure / washout / drying / anti-tack complete functions in one unit.

Enable simple / easy / quick / convenient / clean operations for liquid matrix plate making.

Free thickness, any size as you like to make matrix plate in your plant quick and economically.

Don’t have to prepare lots of different thickness and size photopolymer plate in your stock.

Using base film good for back exposure and easy cut to size not difficult as metal based plate.

Any gauge matrix plate up to 7 mm at low cost as you like. No more expensive metal etching.

UV curing to harden the image and washout only by water green and no pollution any more.

Excellent heat conduction and transfer clear image. Base film heat resistance 190 degree C.

Cost is only 1/3 of photopolymer matrix plate. Product quality is perfect enough to replace.

How to do when MATRIX PLATE is out of market

YOUR SMART CHOICE INSTEAD

Liquid photopolymer matrix plate

FOR MATRIX MAKING

Liquidpolymer@matrix

Heat resistance 180 degree C Good for stamp matrix making

Melting point 260 degree C Logo / marking for iron casting

No more zinc or magnesium plate etching

Any gauge any size free for you to process

BY UV EXPOSURE AND WATER WASHOUT

Quick / Convenient / Environment green / Low cost