CTP Digital image on flexo plate

CTP Digital image on flexo plate CTP laser for color label

CTP laser for color label CTF Digital inkjet film making

CTF Digital inkjet film making CTF 175 / 133 / 85 lpi dot

CTF 175 / 133 / 85 lpi dot CTS digital image on screen

CTS digital image on screen LaserBlack- black film enhancer

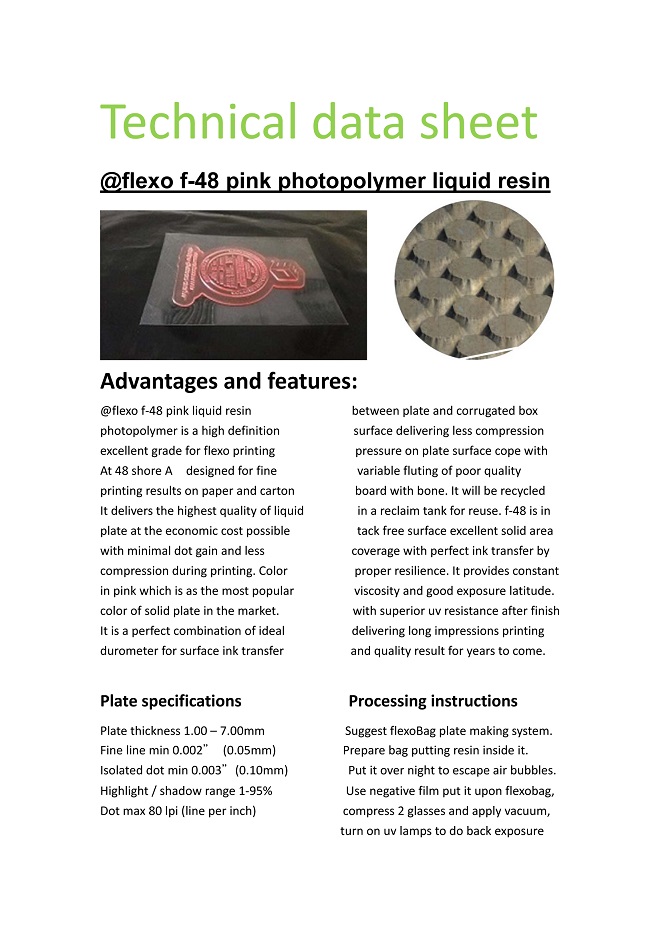

LaserBlack- black film enhancer @flexo liquid plate making

@flexo liquid plate making @flexo plate making machine

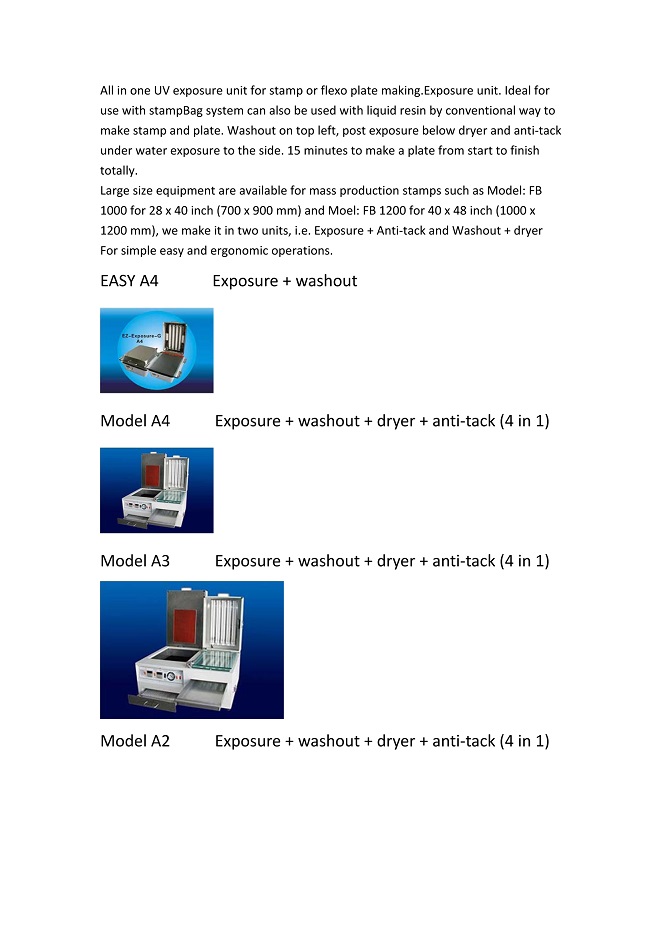

@flexo plate making machine Model: EZ (Easy type)

Model: EZ (Easy type) Model:A4/A3/A2

Model:A4/A3/A2 2436/3040/4050/4260

2436/3040/4050/4260 New automatic washout m/c

New automatic washout m/c Clean & wash after printing

Clean & wash after printing Stamp Making

Stamp Making Photopolymer plates

Photopolymer plates Letterpress plates

Letterpress plates Flexo plates (solvent wash)

Flexo plates (solvent wash) Water wash flexo plates

Water wash flexo plates Digital photopolymer plates

Digital photopolymer plates Liquid photopolymer resins

Liquid photopolymer resins For cup.can.tube.pad printing

For cup.can.tube.pad printing For block print

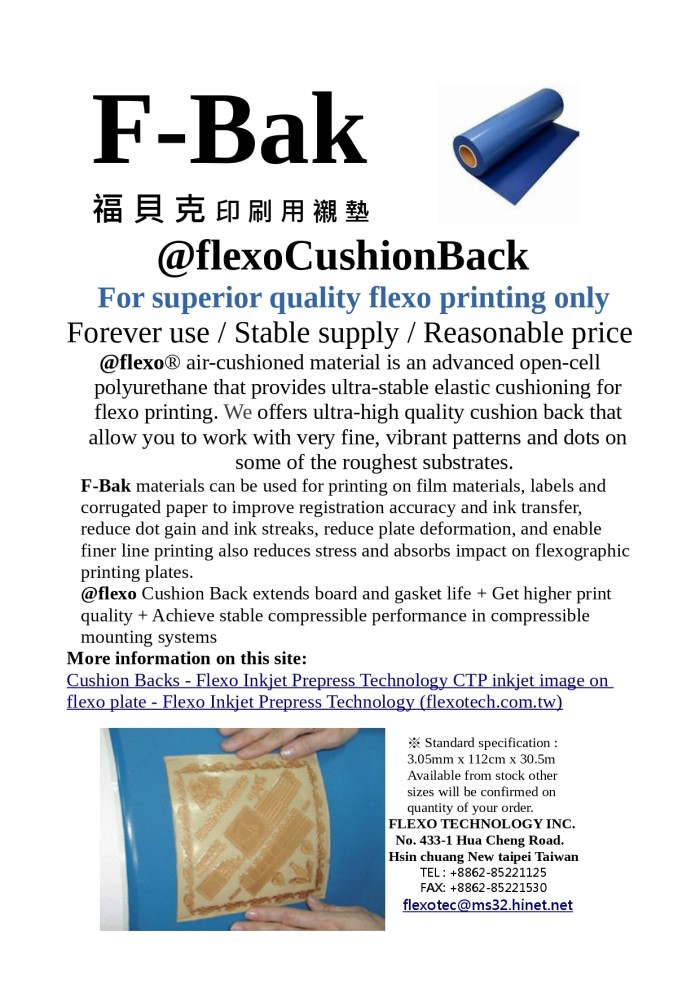

For block print Cushion Backs = F-Bak

Cushion Backs = F-Bak Double-side tapes for printing

Double-side tapes for printing In plant plate making

In plant plate making

View Big Picture

View Big Picture

PREPRESS WHOLE PLANT new installation in Luanda/Angola

![]() Pedro Santos the young, third generation owner of EAL, Edicoes de

Pedro Santos the young, third generation owner of EAL, Edicoes de

Angola in capital city of Luanda / Angola Republic. Found in 26 06 1953 by

his grand father, 70 years history in all kinds of high quality printing with

reputations.

The first plant is located in the downtown area of Luanda, from tag, label to

letterpress printing, from offset to all facilities of converting after printing all

handled in plant.

In 1985, his father started the fist factory of corrugated box (24100m2)

outside city center of 30 minutes, this is the first step for EAL to get involved

in package printing field.

During Pandemic period, Pedro took over the business, and decided to expand

the production of corrugated industry and built up the 3rd factory near the

2nd one, invested in digital color printer to welcome the new era of colorful

boxes.

Now he is aiming at mass production way with automation for beautiful box

with color separation and screening printed by conventional flexo corrugated

machine in order to reduce the costs for high speed production by printing on

corrugated board directly.

With his knowledge and experience of digital color printing, Pedro compared

difference between advantages of laser abrasion machine and inkjet printer for

direct images (No-Film) on flexo plate and eventually selected NozzleBlack

CTP inkjet printer with all machine to complete his flexo plate making

automation project with a very reasonable investment.

Although Angola is located in Africa in the southern hemisphere, the

modernization of EAL plants is not at all inferior anywhere in the world.

He is a young boss ever met before knowing all procedures about printing and

converting for corrugated box. Pedro is 42 year old. (2402011)

TO MAKE AN EPOCH FOR FLEXO PREPRESS

CTP Installation and training in

Kosice / Slovenia

A simple and easy job for NEW prepress workers

---IN plant plate making have reduced 80% of their plate costs---

For flexible package printing, recently we have a new installation of a 42x60 inch CTP Inkjet printer of NO FILM direct image on plate located in Moldava / Kosice / Slovenia.

This is a brand new factory, manufacturing color flexible films for packaging as well as for adhesive tapes, the operation engineers start from knowing nothing about flexo printing by just having experiences in graphic design for years. Now they know everything about how to make plates for colorful flexible film printing.

After installation of the printer and test run it, everything from hardware side is perfect and ready for operating into production. 2 ladies attended the training program from the software side of RIP / color separation / dot screening for which in the past should need at least 2 experienced engineers to do the job, one for image making the other one for plate making. Now only two starters from zero will make the plates for printing production after 5 days course.

The boss couple are quite happy with the system of CTP printer and plate washout unit, by only pay for these small investment to achieve mass function of prepress works in plant. Most important thing is that to save them much money (80% of cost), labors and waiting time for the production if they will out sourcing the plate making.

Flexo plate making

IN-PLANT why?

No matter you are a label / flexible packaging / corrugated box flexo printer, it is important and necessary to have your plates made at your own factory. This is nothing to do with money, but it will grant you ten advantages as below:

A. Time saving

B. Waiting time saving

C. Transportation saving

D. Quality controllable

E. Complete line for high production

F. RD for new future.

G. Cost saving 80% than our sourcing

H. Use new equipment and technology for low capital investment.

I. Keeping your own business secrete and customers secretes.

K. simply one click to operate anybody can do it. No need to have skilled engineer any more.

J. No more digital plates use your conventional plate.

When you are out sourcing for plate making outside the factory it will be time for sending / waiting for production / delivery back to your plant. The quickest maybe 1 day – next day delivery but in many areas it will take at least 1 week or even more. In some case may have to go out side the country then sending back to you which may take 2 weeks to 1 month.

These time waiting may lose interest of customer keeping on giving you printing order or even go to your competitors who are doing in their own plant will make delivery quicker than you. In addition, time waiting will also affect your printing productivity and cash flow.

Now a days it is easy to send a file by internet or other tools but still after plate is made has to deliver back to you. The quicker the delivery, the higher the cost of transportation fees. In-plant plate making will delete all these costs for you.

As printing press foot print is so important for not only the press but also for each of color printing units therefore it is very free and easy for you to calibrate each printing unit in your factory and adjust it from your own plate making conveniently. So as to the improving of your printing quality as you like just inside your own plate making room.

Normally a boss knows how to buy a good machine for the production, but a smart boss will also think of it is important to build up a prepress room by using the new developed technology and equipment for capital investment saving and more efficient. By which to complete the full production line in plant completely.

For RD purpose (Research and Development) is also an advantaged way of thinking for a factory. May sometimes also getting grants from government authorities. But it is easy and convenient for your prepress room to conduct new projects for your own future. A clever boss may give extra bonus to encourage employees for creating a new product or project.

Many bosses told us that after having their own plate making in plant have saved their out sourcing cost a lot, up most to 80% saving if compare with it is in the past with our sourcing expenses. Bosses are quite happy for the new technology, innovative equipment and application soft wares provided in whole package. As well as earn all advantages mentions here.

New technology means NO-FILM innovation for the future, digitalization makes dream of no film come true for sharper image and film cost saving. For the new equipment a CTP (Computer To Plate) inkjet printer to print a black image on plate directly then to exposure with no film and no vacuum device is now upside down the tradition with low capital investment of inkjet printers.

Most important is keep privacy of you and your clients’ secrete, many printers do not want to leak source of their job in order to protect their business. And your clients also do not like their competitors to know what they are doing now as well as what they will do in the future from the packages you are printing for their future products.

There will be a major saving for using conventional plate you are using is good enough for you to keep on your production smooth, due to not necessary to use particular digital plates for our inkjet CTP, you do not have to change to use plate other than your favor for the best printing result you are requiring. You just use the plates you are normally use.The price difference for a digital plate is about 30% higher.

FLEXO TECHNOLOGY INC. (FTI) HAS THE ABILITY AND RESPONSIBILITY TO HELP YOU BUILD UP YOUR OWN PLATE MAKING IN-PLANT WITH ADVANCED EQUIPMENT, NEW TECHNOLOGY AND SOFTWARE OF LOWEST CAPITAL INVESTMENT BUT HIGH PRODUCTION WITH HIGH QUALITY.

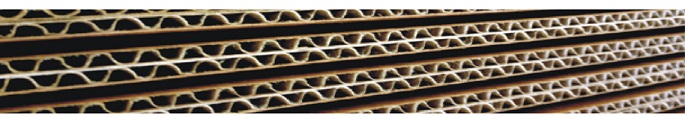

ONLY WAY FOR HIGH QUALITY CORRUGATED BOARD PRINTING

NO MATTER HOW ROUGH and TOUGH IS THE SURFACE

F-Bak 福 貝 克 印 刷 用 襯 墊 @flexoCushionBack For superior quality flexo printing only Forever use / Stable supply / Reasonable price @flexo® air-cushioned material is an advanced open-cell polyurethane that provides ultra-stable elastic cushioning for flexo printing. We offers ultra-high quality cushion back that allow you to work with very fine, vibrant patterns and dots on some of the roughest substrates. F-Bak materials can be used for printing on film materials, labels and corrugated paper to improve registration accuracy and ink transfer, reduce dot gain and ink streaks, reduce plate deformation, and enable finer line printing also reduces stress and absorbs impact on flexographic printing plates. @flexo Cushion Back extends board and gasket life + Get higher print quality + Achieve stable compressible performance in compressible mounting systems More information on this site: Cushion Backs - Flexo Inkjet Prepress Technology CTP inkjet image on flexo plate - Flexo Inkjet Prepress Technology (flexotech.com.tw) ※ Standard specification : 3.05mm x 112cm x 30.5m Available from stock other sizes will be confirmed on quantity of your order. FLEXO TECHNOLOGY INC. No. 433-1 Hua Cheng Road. Hsin chuang New taipei Taiwan TEL : +8862-85221125 FAX: +8862-85221530 flexotec@ms32.hinet.net

Plate making & Printing

WORKING TOGETHER

It is a very simple philosophy that plate making is a part of production to your printing process. In the past most of the printers rely on art work and plate making house to make plate outside ready for on press printing.

That was due to needing skilled artwork personnel to do the typing / drawing / layout then to make a film for reproducing image and finally exposure the image on a plate in order to make a plate for printing.

Now a days, artwork is no longer a skilled job and can be anybody, by using a computer any body can click and arrange for the type setting / drawing

/ photo to layout a plate ready image for plate making and then output

an image immediately for plate exposure no matter it uses film or no. No process camera / image setter / developing equipment is necessary any more.

For plate making part, due to digitalization and automatic process , the plate making machine are now easy to operate by quick education and training no professional technician is required for this prepress job, any body who knows how to click a computer is able to make a plate beautifully and quickly. These are gifts from automation which makes it possible for plate making in plant and depends on outsourcing not any more.

For flexographic and letterpress printers this is becoming a new trend to make your own plate as a part of printing production.

As to automation of flexo and letterpress plate makings, no film direct image on plate are getting popular now, from a flatbed inkjet printer you can have your

image on a plate directly using no film any more and you can exposure the plate on the printer either, no more exposure machine with vacuum sheet is necessary.

Meantime, automatic processor is also convenient for plate making, after exposure move from printer into auto washout machine in minutes you can have your plate ready for printing.

These are new weapons for after pandemic business, you may have to think of using it when you want to recover quickly from the spreading, meantime in plant plate making will save a lot of time, labor and cost for you.

FLEXO PREPRESS AUOTOMATION

For corrugated box mass production

A. @flexo CTP printer- No film inkjet direct image

on any plates

NozzleBlack CTP printer – no film, direct image with exposures on printer.

New Model: CTP 1550-4260 working size: 1070 x 1530mm (42x60 inch)

Complete unit equip with IR lamp drying image quickly / back exposure UVA lamps under flatbed glass / Led UVA to harden the plate surface right after image printed / RIP software

paying annual fees to software company by yourself.

B. @flexo Automatic Washout machine

Water wash and Solvent wash type for your choice

@flexo Automatic Washout m/c is a computer touch screen control system with automatic solvent replenish by constant temperature; the plate washout pressure can be set arbitrarily, which is suitable for making various plates of any thickness plate. The brush is made of high-quality filament.

The main washout board uses round brush + flat brush staggered washing and the width of the flat brush is widened, which can play the role of more smooth relieved area of the plate. The final cleaning department is a climbing plate washing, which is used to clean off completely the residual traces of the plate.

The bottom cleaning brush and the rear cleaning brush use a one-time new solvent, which flows into the circulating tank naturally after use. There are 13 brushes for the whole machine. The brush drive system is equipped with a frequency converter, and the plate washing speed can be adjusted arbitrarily, which is suitable for various high-precision digital plates and ordinary flexo plates or printing plate cleaning after printing.

The equipment uses a combined transmission motor, and the transmission adopts a sturdy and durable bevel gear transmission. All parts in contacting with solvent are made of 304# stainless steel. Also equipped with suction and exhaust fans. Recently, this model has been supplemented and upgraded that front second, fourth and two roller brushes swing left and right, which can speed up the washing speed and cleaning the plate.

The arc hooks on both sides of the entry knife with plate can move left and right, which is convenient for fine-adjustment. Unlike the previous model that entry knife and the hook cannot be adjusted. The wiper blade is changed to a uniquely designed wiper groove to make the brush wipe cleaner. You will like this new improved washout machine definitely.

C. @flexo Dryer + Treatment + Post exposure unit

The plate drying machine is equipped with a four-layer plate drying cabinet. The temperature difference machine has uniform controlled everywhere, and a constant temperature device is set for heating to ensure that the temperature difference of the oven is ±≤3℃, and the accuracy of the color registration requiring jobs of the printing plate in order to prevent from being affected by the uneven temperature difference. Set up automatic control in constant temperature air intake and strong exhaust air device to ensure uniform wind and temperature and remove ozone in time in order to dry up speedy and for plate long time printing.

As to treatment part of anti-tack to remove the sticky of plate, imported 36W/UVC lamp is used as the light source. All of the lamp caps and electrical components are isolated from the lamp tube in order to prevent ozone from corroding the electrical components during the anti-tack process. A powerful ozone removing device is installed to prevent ozone from corroding the equipment and affecting the quality of the plate quality.

Three equipment are good enough for

FLEXO PREPRESS AUTOMATION SYSTEM

PPD BROUSSE Clichés

Ales / France

Ales is a village in France full with grape yards, about 120 kilo meters away from the beautiful city in south France of Marselle port. PPD BROUSSE Clichés is a traditional flexographic plate making house since 40 years ago. Mr. Daniel Brousse is the boss and his son Michael Brousse is the operation manager.

Daniel’s brother in law is running a corrugated box factory providing boxes for all grapes and wines, therefore they have to rely independently on them to make flexographic plate for printing jobs. The mother started to make the plate from design / art work / film making……. since 80’s. Now Michael has to work hard in order to provide plate making service of the box factories for all the city / village near around. Fortunately, now they have this CTP direct image printer to help them for the busy and tight production.

Before having this CTP inkjet printer, they used an inkjet printer to make film which is not necessary for them to invest extra money on a camera, processor and related equipment by using photo film which will no longer exist soon. This experience is helping them a lot and has make them to get acquaintance with operating this inkjet CTP printer for direct image on flexographic plate quickly and easily.

After the installation of hardware and inputting the RIP software into their computer as well as entering to their in house operating system. The next day, Michael starts to print images on the plate directly without using film. The UV lamps are equipped with the CTP printer under the flatbed for plate back exposure which is convenient for them no need to turn over the plate in the room which is not big, as well as the LED / UV on the inkjet head hardening the surface of the plate immediate right after print protecting any possible damage of image from moving the plate to washout processor which is not quite close and when a plate is not small.

Satisfactorily, they are all happy about the performance of hardware and enjoying so many choice of settings from the RIP software, besides of no film / no vacuum / sharp Image and easy operation, take all the advantages when the shop is not in a big space, not so many operators and processor is not in a nearby place for the big size plate making.

Michael is delighted personally because of this printer of no film, no vacuum and no turning over side of back exposure in line, will save him 15-20 minutes of processing time each big plate. Now he is not afraid of more jobs come in for he can handle it easily with this machine which means that he is able to enjoy finishing every weekend with his families now.

How to make more money

as a corrugated box printing factory

Minimum capital investment of automatic system and equipment

Rest of technical / maintenance / service just rely on our training

CONG TY TNHH BAO BI GIAY DOANH THAI corrugated box printer, located in Song

Than Industrial Park, Binh Duong Province, Vietnam has been using our FlexoBag plate

making system since 2010 in their 1st factory.

At that time they are only aiming for the simple and easy combination of using most economic investment for making their negative film by LaserBlack Enhancer in plant from us plus a small sized FlexoBag machine to make their own plate by liquid phtopolymer which is the only way to use no solvent but only water for green purpose in order to substitute hand engraving manually. At the time the skillful worker can do this job well is getting less and less gradually.

Five years later in 2015, due to the smart choice of this in plant plate making system LaserBlack + FlexoBag, to speed up the production as well as reduce cost of printing plate down to 20% or even 10% only than other printers who has rely on plate making outside in the trade shops, this can’t say that it is not a big sum of saving. The boss started to build a 2nd factory which is 5 times bigger in size than the 1st one. They purchased a set of medium size machine from us.

Then in 2019, they start to establish the 3rd factory which is 5 times bigger again and it is 25 times bigger than the 1st factory. The factory is now as big as a school in the south part of VN near Hochiminh city. At this kind of facility they have to change to a biggest system of FlexoBag machine to make plate and for negative making, as well they have to use CTF Computer To Film system from us by inkjet printer to make negative film and plate 24 hours a day in 3 shifts.

This is telling a story that to make plates in plant is definitely a trend of box printer to make their own plate to save time / labor and reduce plate cost to 10% of your out sourcing plates most important is to increase the efficiency of your production if the boss has bright eye to see their future by using the proper system and equipment.

Why printers have to

flexo plate making in plant

In the past days over the world or even in Japan now, most of corrugated printers (95%) are outsourcing their plate for they may presume that plate making is a total different production for a box printing company.

Now a days, they found the profit of outsourcing plate is taken so much from them that many corrugated factories are getting interest in making their own plates in plant from which may reduce this part of cost to only 10-20 % from what they are paying every month.

They may think of complications of first, film making then plate making, to hire more people for this purpose, no easy to have skilled engineers for the job. Most important is considering if there is a SOP to success the plate making. After they buying the equipment may just increase they capital investment and cause other problems of people management.

Obviously to save cost of everything inside the manufacturing factory is a trend for every industry now. Less people to work in plate making room with contemporary equipment of digitalization and automation by investing less cost machine for future production, this dream of 80-90% cost saving of your plate can come true.

Due to trade war between countries, JP corrugated box factories are predicting a recession is coming soon, for this reason, they have to cut off the high cost items and put into first innovation list. Changing from outsourcing plates to make it in plant is almost the first consideration and decision now so as the same way of thinking in Korea.

CTP (Computer To Plate), direct image without using film by inkjet printer is a first choice of economic investment for plate making now a days. With automatic washout machine for SOP process. Both are good and important weapons for digitalization and automation as well as for less cost effective investments. Two persons are required in the plate making room, and raw material cost is also limited to the photopolymer plate in boxes only.

Die makers => flexo plate making

Die making and flexo plate making seems nothing to do each other with no intersection at all. But actually both of the industries are using a same drawing / design for production. As a matter of fact, die drawing is only a little bit bigger surrounding of the image drawing.

For a die maker looks difficult to start with plate making, but due to inkjet printer and supported by various software, it is now everything in digitalization and automation. For color separation and dot screening jobs it is no longer like in the old days needing well trained engineers to work for a long time. As in 50 years ago a 4-color separation job can be made 4 sets in a day, and for the screening job you have to repeat again and again until it is found proper from a printed proof.

Everything is under SOP (Standard Operating Procedure) now, as long as a click no matter who push the button and with experience or not. In addition to the image making part, a CTP (Computer To Plate) direct image on plate system can give color separated and screened dots perfectly from an inkjet printer with RIP (Raster Image Processor) software to do all jobs directly on plate without film, which was not possible for an unskilled person to do it so quickly.

As to the plate making process, due to technology of inkjet direct image on plate, exposure problem caused by vacuum to ensure no air in between film and plate are now all avoided. With automatic plate processing equipment, you just put it into auto washout machine after UV exposure. A beautiful plate is coming out in few minutes waiting for drying and finishing then to mount on printing press. By these innovative machine, flexo plate making is as easy as die making now.

This is a proper timing for people who want to make plate and die together in order to serve the same customers with same drawing (file)

Or who is now suffering with no technical engineer to do the job / no SOP of plate making / lack of plate making technology, it is good for you to consider and start it now. For we have many experience to help die making customers switched to plate making successfully in the world.

corrugated box printing factory

PLATE MAKING SYSTEM

from

so many combinations for your investment

Above prices are FOB Taiwan. Freight will be quoted upon your order with consumables

.

After the installation and training we rely on their engineers to practice and practice in order for getting more and more experience after our engineer go back to Taiwan especially for the trouble shootings. Because Qpack is new on plate making, before now, they rely on out sourcing, which have to wait a long time and long distance for delivery.

When first plate was made and test printed from their press, the owner smile up satisfactorily on his face. From now on they do not have to wait so long for a plate.

Prepress room total solution for VN

Keeneye company in Hochiminh city / Vietnam is keen in building up their own liquid photopolymer prepress center in for their growing business, to reduce their costs of using solid plate and washout solvent.

In 2014 November when All-in-print show held is Shanghai / China, Mr. Thien boss of the company came to the exhibition and consult details for using which system is better for theie prepress room:

1. Solid plate by water washout or liquid photopolymer by water wash ?

2. Using CTP direct image on plate / CTF to make negative film ?

3. NozzleBlack is better or LaserBlack to make negative film to save cost ?

In consideration of green environment with factory safety and health of employees, they have decided to use liquid resin @felxoBag system because water wash flexo plate raw material is too expensive for them. (Eventually they have decided model : FB 1200 for plate making up to 1000 x 1200mm)

As for negative film making considering of both equipment and production costs, they will use LaserBlack to make negative film. On July 2nd 2015, the machine have loaded on board toward their port, and engineers from Team @flexo will be on the way to build the machine as well as for training by end of July.

Keeneye has estimated to print with their own plate on 1st of August 2015.

After installation + training in VN

Keeneye company is a professional solid plate making shop for corrugated / label / flexible package printers by using solvent washout plate since 2010. VN government has announced to strict control for using of Perc recently therefore they have no other choice but only to use liquid resin system by water washout. To avoid air bubble is a major issue for them from a liquid plate, if they paying a lot of money to invest advanced machine will be able to avoid air-bubble problem during plate making quickly, but the cost they will pay for it will be difficult to return for the huge amount so it is out of their consideration.

After comparing and comparing, in 2014 November when they see the world patent system of @flexoBag machine show on All-in-print in Shanghai they have decided to use it. Keeneye was making only solid plate, therefore their customers are always checking the liquid plate from solid plate standard of view, so the liquid plates made by them have to be good in fine reproduction / sharpness / even thickness / nice surface in order to be able to compare with a solid plate.

in addition, because they are a plate trade shop, the quantity of plate making is large sometimes up to 10 m2 per day. Due to flexobag can be prepared in advance before palte making instead of treating bubbles on the machine, the bags can be used quickly as a solid plate ready for exposure, since liquid resin exposure and drying time are shorter than a solid plate, therefore whole process can be finished in 20-30 minutes which is much shorter than solid plate and cost of it is only 50% of a solid plate.

Fortunately @flexoBag system can meet their request of quality / speed / cost, the profit from it can cover the invest capital easy and quickly. Moreover @flexoBag plate making system is an environment protection and green products, so all members in the factory are happy and healthy.

Chang Yuen Paper packing Co. , Ltd. VN ,

Lo J1, duong NA3 – DA3 KCN My Phuoc II,

Huyen Ben Cat Tinh Binh Duong , Vietnam

Experiencing new @flexoBag plate making technology

To whom it may concern:

We are a corrugated paper company with 6 flexo printer /slotter in our factory, before we make our own plate in lant, we are paying about USD 2000.- of photopolymer plates each month from the trade shops near around. Besides this, we have 10 people making hand engrave plate and a laser engraving machine making rubber plates for not so fine image jobs. Due to growing business, the owners have decided to make our own plate in our plant. Photopolymer plate making is a brand new item for us, so we have started to search for new technology of equipment and materials in order to improve our printing quality as well as for expanding our future business. Eventually, we have found @flexoBag System is a brand new technical for photopolymer plate making to meet our requirements of low investment, quick process and environment green for us. The total equipment cost with consumables for initial starting cost us USD .- for a 60 x 90 cm size machine which is quite practical for our use and quick process of the system has increased a lot of our productivity. By the end of December 2010, we are expecting to have our investment return, for we have found the total cost of the production including everything is less than 20% of the plates we rely on trade shop before.

The owners know that using this new system is worth with no regret now.

Feedback from Indonesia

PT PREMIER JAYA INDO

JL RAYA PERTAMINA NO 8 SUMBERAME

WRINGINANOM GRESIK INDONESIA

We are corrugated board company in Surabaya / Indonesia , due to labor wage increasing gradually and it is not easy to find skillful hand engraver to make rubber plate with many small letters on it, we must to find out a simple, easy economic and green way to make our own printing plate for printing the cartons in plant.

Moreover, it is getting expensive for the plate we rely on trade house to make for us outside, so that we have to pay too much plate making fees every month, and it is becoming not a small sum as USD 20000.- annually. Therefore we start to search a good way to solve these problems for us and eventually we have found @flexoBag system from internet.

The website is neat and clear enough to let us know everything about the new system with the DVD, the Q&A and the Feedbacks from their users by which we have found some of their users are in the very similar production

situation with us. After having the comprehensive information, we have decided to place our order immediately in order to start up the plate making right after our New Year Holidays which is in the mid of September 2010.

Two of @flexoBag engineers come from Taiwan at the beginning of October right after the machine had reached us and in 5 days, now we are able to make our own plate smoothly. Printers are happy because of no need to wait for plate delivery from trade shop any more or even have to go to collect the plate when we have to use it urgently.

This was our first transaction with @flexoBag company and we only know them from internet. At the beginning we do not have full confidence in the first transaction with big amount to them. With regret now we have to place another bigger order to them only in few weeks after the installation to buy consumable materials such as Resin and Film from them and most important is their LaserBlack Enhancing Solution to enhance print as negative film from our HP printer works too well that we have to order more as well. It is really a genius invention from them again that we can even make our own negative in our plant for in time plate making now by which we do not have to rely on outside service from image setter to make negative film for us at all.

I have to admit that we are not only happy with the @flexoBag system but also we have to thank them for their skillful and quick service offered to us to do training to our people for both plate making and for the machine maintenance.

They are quite professional!

Wenyao He

- NGHIEP -

CHIN CHIA PACKING & PRINTING FACTORY

GCANG-MING MANAGEMENT DISTRICT

DONG-CHENG TOWN , DONG-GUAN CITY , GUANG-DONG , CHINA

We are Chin Chia package printing company located in Dong Guan where is a major manufacturing city for all kind of goods export to most of the countries all over the world.

Our job is making and printing film bags, paper bags and corrugated box supplying to the factories located in this area. At the beginning we use conventional flexo plate, but because of the green environmental requirement is getting higher and higher so that we have decided to find a more friendly method to make plates.

We have made flexo plate by solvent washout for quite a long time, until it was a good chance for us to see this new announcement of water washout flexoBag system during DRUPA 2008 in Dusseldorf Germany, after the show we have made several visit to see the demonstration of how to make a bag, how to fill in the liquid resin, exposure, wash by water and request for making plates for our test printing on line to proof not only for the reproduction but also the long impression running of the plate made by the system for it is a brand new technology in the flexo printing industry.

All of employees hate the strong solvent odor so much that we have to decide to use this water wash system as soon as possible. The solvent recovering department people, now they join us in printing room, for they have lost their job already. In addition to these, plate making room is no longer a dirty place like before any more.

The happiest person should be our boss, not only for the production cost have been reduced 40-50% and processing time very short, most important is that the boss has returned all his investment back by now mostly because of using no solvent any more.

In spring of 2009, we started to use @flexoBag plate making system, now we could not print without it for everybody love it, even our former plate making shop is using the same system following us.

Pre press Dept. We are very happy and healthy with @flexoBag

I am delighted to report that the @flexoBag system works well in our factory since July 2009. I made some excellent plates from liquid photopolymer by using the flexoBag system and use only water to wash it out, it is very incredible that the plate is the same quality with the solvent washout flexo plates. Now all the people in the prepress room are very happy with it because of no disgusting odor in the factory any more, every body looks very healthy now.

Due to flexoBag can be prepared in advance before plate making, the bubbles are disappeared therefore it is very easy and quick (50% time consumption only) to use by just putting the film and bag in between two glasses do not have to pour in resin waiting for spreading and take off the bubbles on the machine, so the exposure process is now simple and easy for us in stead of the hard works of spreading the thin film and paving the base film (because the bubbles may happen again during this procedures).

No spreader, no coater and no bubble happened, the machine is very simple so the cost of investments we have paid is only 30% of the conventional machine cost, plus the production cost is only 50% of the solvent wash flexo plates therefore we are expecting to have our return of investment quicker by June of 2010 definitely.

All of our employees like this new flexoBag system very much

Hen Cog

Chi Fan Enterprise Corp.

_______________________________

22-27 Tienmu West Road

Taipei , Taiwan