CTP Digital image on flexo plate

CTP Digital image on flexo plate CTP laser for color label

CTP laser for color label CTF Digital inkjet film making

CTF Digital inkjet film making CTF 175 / 133 / 85 lpi dot

CTF 175 / 133 / 85 lpi dot CTS digital image on screen

CTS digital image on screen LaserBlack- black film enhancer

LaserBlack- black film enhancer @flexo liquid plate making

@flexo liquid plate making @flexo plate making machine

@flexo plate making machine Model: EZ (Easy type)

Model: EZ (Easy type) Model:A4/A3/A2

Model:A4/A3/A2 2436/3040/4050/4260

2436/3040/4050/4260 New automatic washout m/c

New automatic washout m/c Clean & wash after printing

Clean & wash after printing Stamp Making

Stamp Making Photopolymer plates

Photopolymer plates Letterpress plates

Letterpress plates Flexo plates (solvent wash)

Flexo plates (solvent wash) Water wash flexo plates

Water wash flexo plates Digital photopolymer plates

Digital photopolymer plates Liquid photopolymer resins

Liquid photopolymer resins For cup.can.tube.pad printing

For cup.can.tube.pad printing For block print

For block print Cushion Backs = F-Bak

Cushion Backs = F-Bak Double-side tapes for printing

Double-side tapes for printing In plant plate making

In plant plate making

View Big Picture

View Big Picture

ONLY WAY FOR HIGH QUALITY CORRUGATED BOARD PRINTING

NO MATTER HOW ROUGH and TOUGH IS THE SURFACE

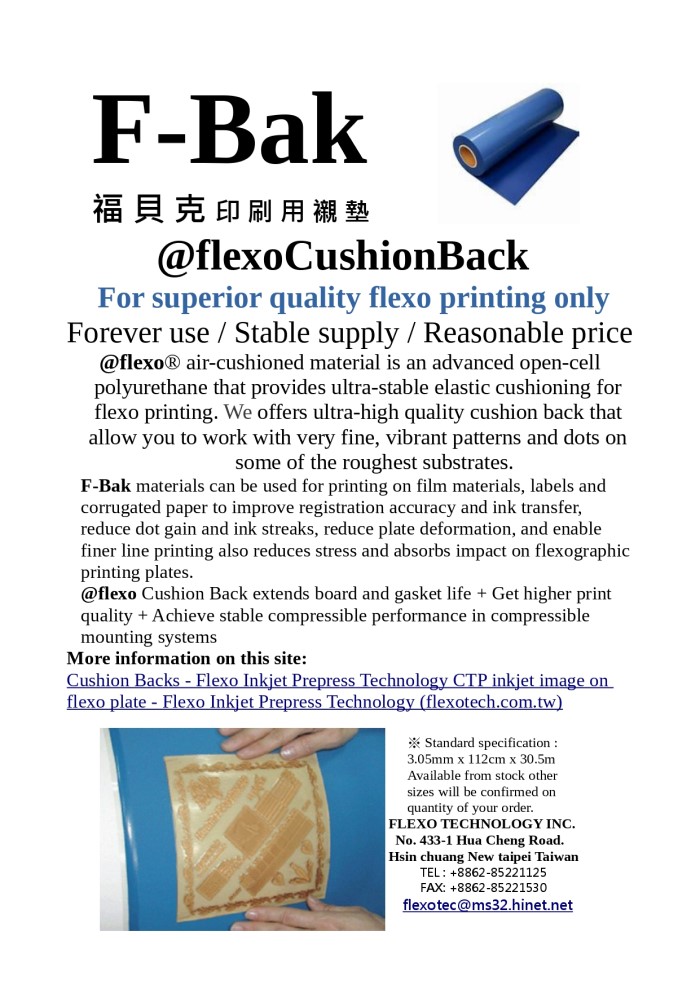

F-Bak 福 貝 克 印 刷 用 襯 墊 @flexoCushionBack For superior quality flexo printing only Forever use / Stable supply / Reasonable price @flexo® air-cushioned material is an advanced open-cell polyurethane that provides ultra-stable elastic cushioning for flexo printing. We offers ultra-high quality cushion back that allow you to work with very fine, vibrant patterns and dots on some of the roughest substrates. F-Bak materials can be used for printing on film materials, labels and corrugated paper to improve registration accuracy and ink transfer, reduce dot gain and ink streaks, reduce plate deformation, and enable finer line printing also reduces stress and absorbs impact on flexographic printing plates. @flexo Cushion Back extends board and gasket life + Get higher print quality + Achieve stable compressible performance in compressible mounting systems More information on this site: Cushion Backs - Flexo Inkjet Prepress Technology CTP inkjet image on flexo plate - Flexo Inkjet Prepress Technology (flexotech.com.tw) ※ Standard specification : 3.05mm x 112cm x 30.5m Available from stock other sizes will be confirmed on quantity of your order. FLEXO TECHNOLOGY INC. No. 433-1 Hua Cheng Road. Hsin chuang New taipei Taiwan TEL : +8862-85221125 FAX: +8862-85221530 flexotec@ms32.hinet.net

Best quality cushion backs

Flexo technology behind the printing plate

Flexographic cushion backs from @flexo group has been in the market near 50 years. Gaining positive and popular reactions over the world.

The faster running speed and demand of higher fine dot reproduction are good reasons to use highest quality cushion backs and use it forever.

For middle quality printing machine or old press, don’t worry @flexo backs will reduce the gear bounce to increase printing speed and getting better result for you.

This is what we called it, flexo technology behind the printing plate.

During this pandemic spreading period, plenty stocks of cushion backs are waiting for your choice.

With Magnetic Edge Forever Use

Easy to mount and take off

Thickness : 3.05 / 4.06mm. Available in any size you need

Quick delivery by EMS air freight door to door service.

New Model : M / back

Cushion Back Technology

※ Smart way to use any thickness plate you like for printing.

※ The thinner the plate you will get the better printing results.

※ F / back is an open cell technology product can use forever.

※ Magnetic strip will be helpful to mount on / off the cylinder.

※ Convenient and economic to mount for the image areas only.

※ Other advantages are all the same as F / back during printing.

F/back S/back M/back |

for faster and better printing results Flexo cushion backs Economic Sticky Cushion Backs

@flexoback Cushion backs forever use

Applications : Technology behind the printing plate @flexo Cushion backs forver use

※ Special developed for flexographic printing.

|