CTP Digital image on flexo plate

CTP Digital image on flexo plate CTP laser for color label

CTP laser for color label CTF Digital inkjet film making

CTF Digital inkjet film making CTF 175 / 133 / 85 lpi dot

CTF 175 / 133 / 85 lpi dot CTS digital image on screen

CTS digital image on screen LaserBlack- black film enhancer

LaserBlack- black film enhancer @flexo liquid plate making

@flexo liquid plate making @flexo plate making machine

@flexo plate making machine Model: EZ (Easy type)

Model: EZ (Easy type) Model:A4/A3/A2

Model:A4/A3/A2 2436/3040/4050/4260

2436/3040/4050/4260 New automatic washout m/c

New automatic washout m/c Clean & wash after printing

Clean & wash after printing Stamp Making

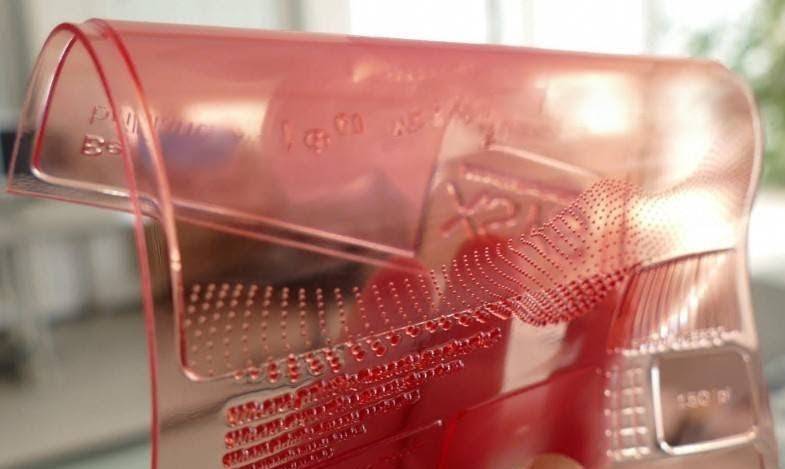

Stamp Making Photopolymer plates

Photopolymer plates Letterpress plates

Letterpress plates Flexo plates (solvent wash)

Flexo plates (solvent wash) Water wash flexo plates

Water wash flexo plates Digital photopolymer plates

Digital photopolymer plates Liquid photopolymer resins

Liquid photopolymer resins For cup.can.tube.pad printing

For cup.can.tube.pad printing For block print

For block print Cushion Backs = F-Bak

Cushion Backs = F-Bak Double-side tapes for printing

Double-side tapes for printing In plant plate making

In plant plate making

View Big Picture

View Big Picture

![]()

PREPRESS WHOLE PLANT new installation in Luanda/Angola

Pedro Santos the young, third generation owner of EAL, Edicoes de

Angola in capital city of Luanda / Angola Republic. Found in 26 06 1953 by

his grand father, 70 years history in all kinds of high quality printing with

reputations.

The first plant is located in the downtown area of Luanda, from tag, label to

letterpress printing, from offset to all facilities of converting after printing all

handled in plant.

In 1985, his father started the fist factory of corrugated box (24100m2)

outside city center of 30 minutes, this is the first step for EAL to get involved

in package printing field.

During Pandemic period, Pedro took over the business, and decided to expand

the production of corrugated industry and built up the 3rd factory near the

2nd one, invested in digital color printer to welcome the new era of colorful

boxes.

Now he is aiming at mass production way with automation for beautiful box

with color separation and screening printed by conventional flexo corrugated

machine in order to reduce the costs for high speed production by printing on

corrugated board directly.

With his knowledge and experience of digital color printing, Pedro compared

difference between advantages of laser abrasion machine and inkjet printer for

direct images (No-Film) on flexo plate and eventually selected NozzleBlack

CTP inkjet printer with all machine to complete his flexo plate making

automation project with a very reasonable investment.

Although Angola is located in Africa in the southern hemisphere, the

modernization of EAL plants is not at all inferior anywhere in the world.

He is a young boss ever met before knowing all procedures about printing and

converting for corrugated box. Pedro is 42 year old. (2402011)

PLEASE VIEW DVD demo from :

CTP no film plate making - CTP-噴墨成像+UV+背面曝光 - Flexo Inkjet Prepress Technology CTP inkjet image on flexo plate - Flexo Inkjet Prepress Technology (flexotech.com.tw)

CTP direct image + UVA - CTP-噴墨成像+UV曝光 - Flexo Inkjet Prepress Technology CTP inkjet image on flexo plate - Flexo Inkjet Prepress Technology (flexotech.com.tw)

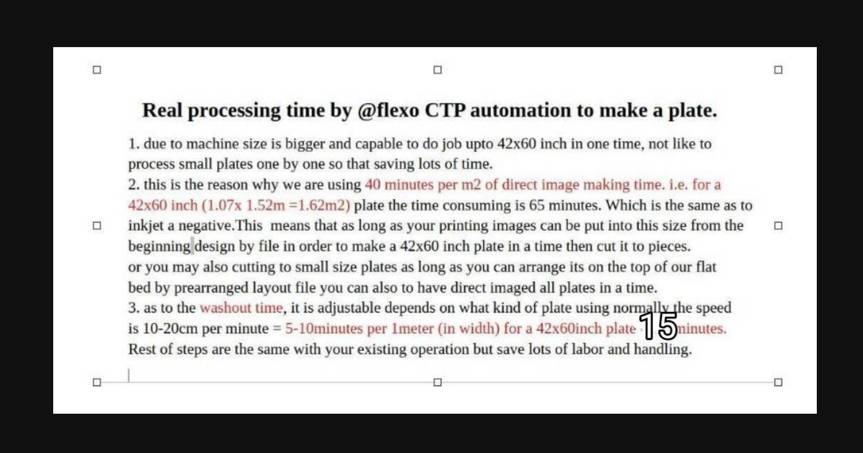

Key functions of a flexo CTP inkjet plate making

Key Point | Details |

|---|---|

Machine Capability | Processes larger plates (up to 42x60 inches) in one run, reducing processing time. |

Direct Image Making Time | 40 minutes per square meter; 65 minutes for a 42x60inch plate 1.62 m² , with flexible layout options. Time as to inkjet a negative film. |

Auto Water Washout Time | Adjustable speed of 10-20 cm per minute, 5-10 minutes per m2, for a 42x60inch plate is 15 minutes with enhancing overall efficiency. |

Total Plate Making Time | Approximately 80 minutes for making a plate in 42x60inch, and leading to significant labor savings. Presuming rest of steps are all the same. |

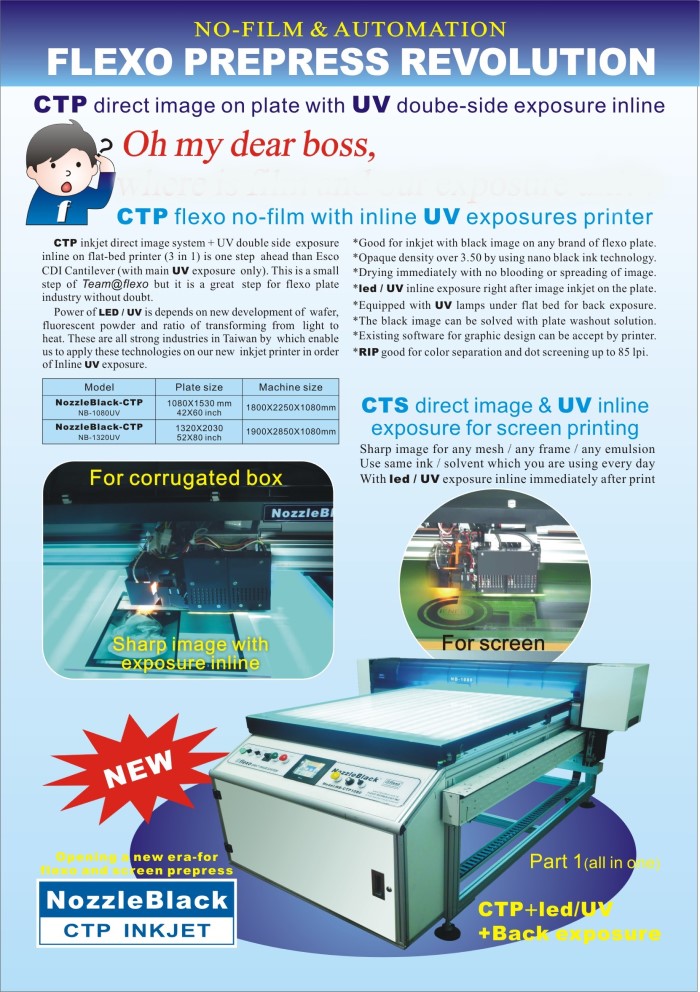

FLEXO PREPRESS AUOTOMATION

For corrugated box mass production

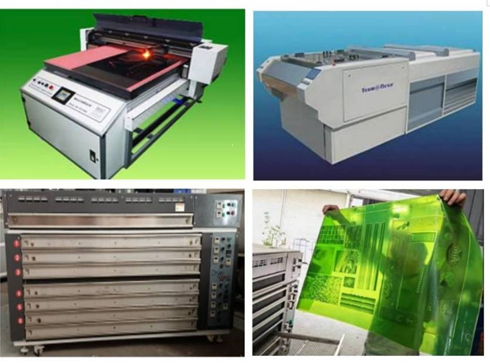

A. @flexo CTP printer- No film inkjet direct image

on any plates

NozzleBlack CTP printer – no film, direct image with exposures on printer.

New Model: CTP 1550-4260 working size: 1070 x 1530mm (42x60 inch)

Complete unit equip with IR lamp drying image quickly / back exposure UVA lamps under flatbed glass / Led UVA to harden the plate surface right after image printed / RIP software

paying annual fees to software company by yourself.

B. @flexo Automatic Washout machine

Water wash and Solvent wash type for your choice

@flexo Automatic Washout m/c is a computer touch screen control system with automatic solvent replenish by constant temperature; the plate washout pressure can be set arbitrarily, which is suitable for making various plates of any thickness plate. The brush is made of high-quality filament.

The main washout board uses round brush + flat brush staggered washing and the width of the flat brush is widened, which can play the role of more smooth relieved area of the plate. The final cleaning department is a climbing plate washing, which is used to clean off completely the residual traces of the plate.

The bottom cleaning brush and the rear cleaning brush use a one-time new solvent, which flows into the circulating tank naturally after use. There are 13 brushes for the whole machine. The brush drive system is equipped with a frequency converter, and the plate washing speed can be adjusted arbitrarily, which is suitable for various high-precision digital plates and ordinary flexo plates or printing plate cleaning after printing.

The equipment uses a combined transmission motor, and the transmission adopts a sturdy and durable bevel gear transmission. All parts in contacting with solvent are made of 304# stainless steel. Also equipped with suction and exhaust fans. Recently, this model has been supplemented and upgraded that front second, fourth and two roller brushes swing left and right, which can speed up the washing speed and cleaning the plate.

The arc hooks on both sides of the entry knife with plate can move left and right, which is convenient for fine-adjustment. Unlike the previous model that entry knife and the hook cannot be adjusted. The wiper blade is changed to a uniquely designed wiper groove to make the brush wipe cleaner. You will like this new improved washout machine definitely.

C. @flexo Dryer + Treatment + Post exposure unit

The plate drying machine is equipped with a four-layer plate drying cabinet. The temperature difference machine has uniform controlled everywhere, and a constant temperature device is set for heating to ensure that the temperature difference of the oven is ±≤3℃, and the accuracy of the color registration requiring jobs of the printing plate in order to prevent from being affected by the uneven temperature difference. Set up automatic control in constant temperature air intake and strong exhaust air device to ensure uniform wind and temperature and remove ozone in time in order to dry up speedy and for plate long time printing.

As to treatment part of anti-tack to remove the sticky of plate, imported 36W/UVC lamp is used as the light source. All of the lamp caps and electrical components are isolated from the lamp tube in order to prevent ozone from corroding the electrical components during the anti-tack process. A powerful ozone removing device is installed to prevent ozone from corroding the equipment and affecting the quality of the plate quality.

These three equipment are good enough for

FLEXO PREPRESS AUTOMATION SYSTEM

CTP Installation and training in

Kosice / Slovenia

A simple and easy job for NEW prepress workers

---IN plant plate making have reduced 80% of their plate costs---

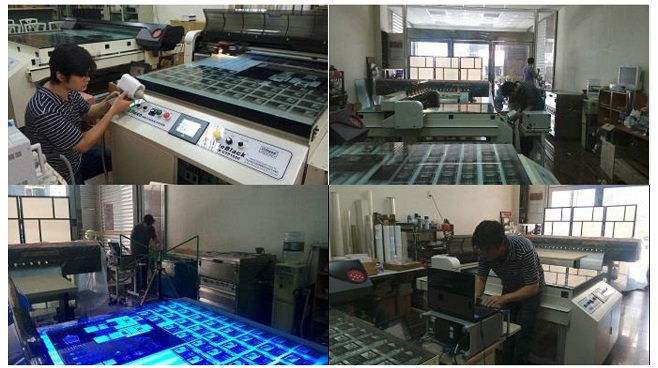

For flexible package printing, recently we have a new installation of a 42x60 inch CTP Inkjet printer of NO FILM direct image on plate located in Moldava / Kosice / Slovenia.

This is a brand new factory, manufacturing color flexible films for packaging as well as for adhesive tapes, the operation engineers start from knowing nothing about flexo printing by just having experiences in graphic design for years. Now they know everything about how to make plates for colorful flexible film printing.

After installation of the printer and test run it, everything from hardware side is perfect and ready for operating into production. 2 ladies attended the training program from the software side of RIP / color separation / dot screening for which in the past should need at least 2 experienced engineers to do the job, one for image making the other one for plate making. Now only two starters from zero will make the plates for printing production after 5 days course.

The boss couple are quite happy with the system of CTP printer and plate washout unit, by only pay for these small investment to achieve mass function of prepress works in plant. Most important thing is that to save them much money (80% of cost), labors and waiting time for the production if they will out sourcing the plate making.

ONLY WAY FOR HIGH QUALITY CORRUGATED BOARD PRINTING

NO MATER HOW ROUGH and TOUGH IS THE SURFACE

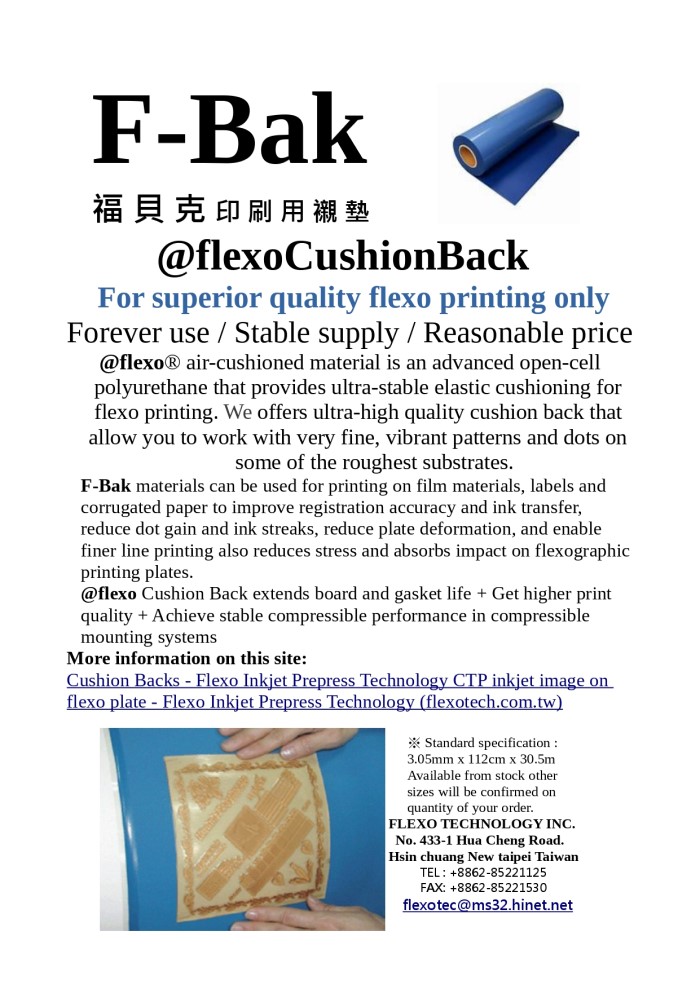

F-Bak 福 貝 克 印 刷 用 襯 墊 @flexoCushionBack For superior quality flexo printing only Forever use / Stable supply / Reasonable price @flexo® air-cushioned material is an advanced open-cell polyurethane that provides ultra-stable elastic cushioning for flexo printing. We offers ultra-high quality cushion back that allow you to work with very fine, vibrant patterns and dots on some of the roughest substrates. F-Bak materials can be used for printing on film materials, labels and corrugated paper to improve registration accuracy and ink transfer, reduce dot gain and ink streaks, reduce plate deformation, and enable finer line printing also reduces stress and absorbs impact on flexographic printing plates. @flexo Cushion Back extends board and gasket life + Get higher print quality + Achieve stable compressible performance in compressible mounting systems More information on this site: Cushion Backs - Flexo Inkjet Prepress Technology CTP inkjet image on flexo plate - Flexo Inkjet Prepress Technology (flexotech.com.tw) ※ Standard specification : 3.05mm x 112cm x 30.5m Available from stock other sizes will be confirmed on quantity of your order. FLEXO TECHNOLOGY INC. No. 433-1 Hua Cheng Road. Hsin chuang New taipei Taiwan TEL : +8862-85221125 FAX: +8862-85221530 flexotec@ms32.hinet.net

NEW DEVELOPED FLEXO PREPRESS AUTOMATION

WITH WATER WASHOUT SYSTEM

DRAGON GOOD YEAR !

At the end of the lunar year rabit, one of our customer mentioned to us that plate making business of color carton for large size printing is pretty busy, so I recommended to the boss that our CTP direct inkjet imaging system, which can be applied black imaging on any plate, free of digital version, no negative fim and no vaccum any more, after exposure can be washed just like the daily operation, which can save the costs caused by the negative film/man-hours/skilled engineer and carefulness handling to avoid wastes of the large size plates during operation and moving as well as waste plates due to poor air absorption, which is very helpful to their expansion of business in the new year of the dragon.

Occassionally our company just has a display machine 42x60 inches for demonstration to be cleared, and we hope to have this factory to use it in order to cause the industry's love, because we have 50 units of sales abroad successfully, and it is a pity that the domestic industry has not shared the nice machine yet.

It is recommended that the boss take advantage of the New Year's holiday to see the information on our website carefully then consider starting to try to make a set of sample plate for the factory to complete the washing and hand over to their customer to test print and compare the printing effect, if satisfied, we will move in the machine to the factory for a month of trial , in order to be familiar with the operation and performance.

I'm glad that the business has been negotiated and done in this way in success, and it can be regarded as a good omen for the Year of the Dragon ! (240323)

POST PANDEMIC FLEXO PLATE MAKING

NO FILM PLATE MAKING FOR FLEXIBLE PACKAGING

Flexible packaging is now a days taking big role in the plastic industry for colorful

package printing. Established in 1974, FTI is still keep on researching of NO-FILM

prepress digital technology for printing industry. In-plant plate making to save

80% plate cost is becoming a trend after the virus spreading this year from

which every factory have to reconsider of new ways in order to welcome this

new change. No film / labor saving / less time / cost reducing are main issues

urgently now. A CTP (Computer To Plate) inkjet printer created by FTI

direct image on any plate is becoming necessary for flexo industry.

NozzleBlack+ new announcement

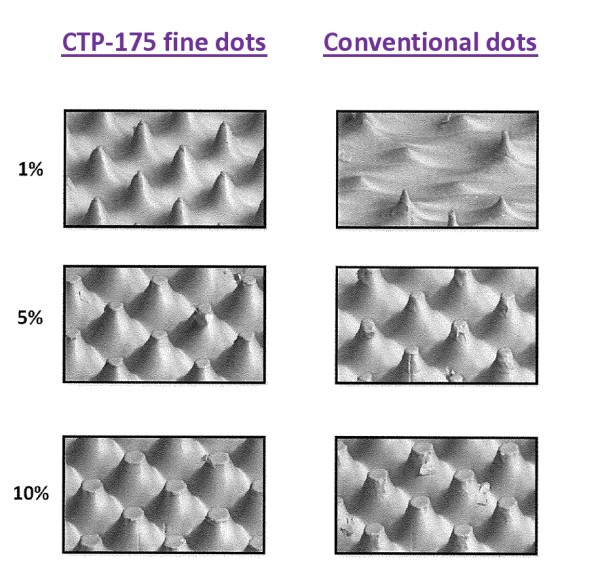

NozzleBlack+ (PLUS) CTP direct image inkjet printer is a brand new product from FLEXO TECHNOLOGY INC (FTI) created recently for flexible package and color label fine printing especially for up to 175 LPI dot reproduction.

This is a new technology combining innovative printer with precision print and versatile RIP software for reproducing dot with find LPI results as good as it is from a laser ablation machine but with much cheaper capital investment.

NozzleBlack+ (PLUS) CTP inkjet printer X-axis (head) is made by a Japanese famous manufacturer with their advanced nozzle technology for fine print as well as rigid bone and body endurable for long time use.

While the Y-axis (flatbed) is special designed by using thick glass for flatness with almost no tolerance under it is equipped with UV lamps for back exposure of plate making which is convenient of no turn over after image is printed especially good for big size plates.

The head is built with an infrared lamp in order to dry up the ink right after print to prevent spread of ink and inflation of the image. Also a LED / UV is installed to harden the black inked surface of the plate for no damage during moving to the washout machine simultaneously.

Anyway, you will like this new NozzleBlack+ (PLUS) CTP inkjet printer as much as it was for the corrugated box printing before. NozzleBlack+ (PLUS) CTP inkjet printer will prove to you for the easy to use, convenient for settings, excellent fine dot reproduction and economic investments by using no negative film and no digital plates. (210308)

Flexo merits to use

NozzleBlack inkjet CTP for no film plate making

Save time and labor

Reduce working procedure

Less employees

Production cost down

Lowest capital investment

Enhance productivity

Saving time and labor

Time and labor saving is becoming an important issue for the printing factory holders after pandemic spreading in the near future.

2.5 million people in the world died away (UP TO 02/23/2021 and may extend in many years) due to COVID-19 virus, lacking of working personnel will be more serious problem than it is before so that bosses have to think of how to reduce labor recruitment or working hours reducing by automation the process procedures to save over time printing jobs. CTP Computer To Plate direct image on your existing printing plate in order to prevent any variation on your production is very important.

Reduce working procedure

During this pandemic period, conventional way of routine production steps have to be reconsidered by the owners of how to less it or how to simplified it. By using this new CTP technology, film making is no longer necessary for plate making.

Elimination of using films to have CTP direct image on plate by inkjet flatbed printer instead, will save your cost of film, developing equipment, maintaining electricity and chemicals. Or saving you a lot of heavy capital investment from buying a laser ablation machine (CDI), in addition using special black coted digital plates may differ from the printing result which is not what you are requiring and expected.

Less employees

Normally no matter using a CTP system or not, an art working person for graphic design is necessary for every printing companies. Now CTP access for plate making is as simple as clicking the keyboard of a computer, so this art working people can also do the job of direct image to plate and exposure. Neglecting skill required of how to escape air between film and plate as well as if it is a close vacuum contact in between will prevent lot of failure plate making by repeating it again. Then just put it into automatic washout machine will complete most important parts of a plate making, in this case at least a workman can be deleted. This will save you from $ 1000 to 3000.per month for a skilled engineer depends on the area, which is a $ 12000-36000 excluding bonus annually only one year of this sum is very easy for you to build up a new CTP inkjet direct image system.

Production cost down

If processed by a laser ablation machine a digital plate with black layer coating is require for the machine which will cost 20-30% more than a conventional flexo plate.

As mentioned labor and time saving, reducing working steps, less employees, use no film and no digital plate, less failure and repeat jobs. All production cost down a lot from these merits despite of less heavy capital invest of the CTP equipment.

Lowest capital investment

An inkjet flatbed CTP printer can process direct image on flexo plate up to 64 x 110 inch (1626x2800mm) as long as and the plate manufacturer can made while laser CDI processing size is only limited at 52 x 80 inch (1320x2032mm).

From the machine side, the cost of a CTP printer maybe only 20-50% of a laser machine depends on the size. The bigger the size will save much more of your capital investment for a laser ablation machine which is limited by the power supply to a big area and depth of a plate.

Enhancing productivity

Cost reduction and productivity enhancing are what every owner want for their business. By using this high tech CTP inkjet printer all members in your factory will cheer up so that jobs can be done quickly, precisely and properly with high spirits these will increase the productivity and create more business opportunity automatically in addition to above mentioned merits.

New jobs always come in from your research and develop, by using this CTP inkjet printer will be simple and easy for you to do various test additionally and trials of making new item or a new products which your customers may want to create and develop for their new products. CTP can help you do it in your own plant conveniently.

Flexo professional journals report

NEW DEVELOPED FLEXO PREPRESS AUTOMATION

WITH WATER WASHOUT SYSTEM

Auto@flexo Digital Washout processor

A BRAND NEW CONTRIBUTION FOR

colorful flexible packaging, labels, boxes anf bags

QUALITY AS GOOD AS DIGITAL PLATE

NO HEAVY CAPITAL INVESTMENT

No more digital plates for CTP plate making?

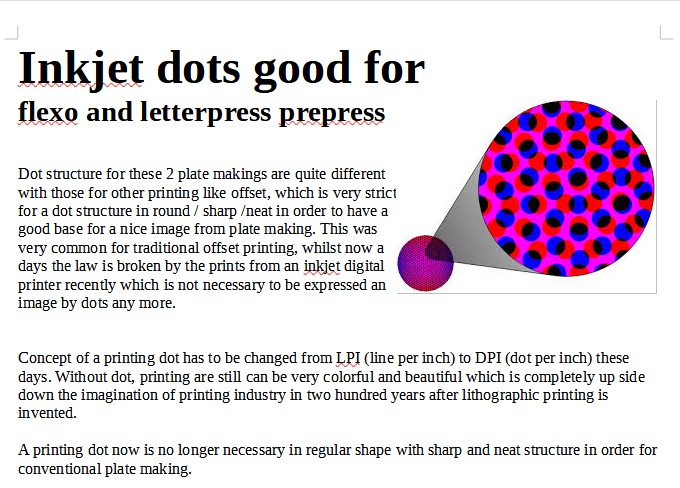

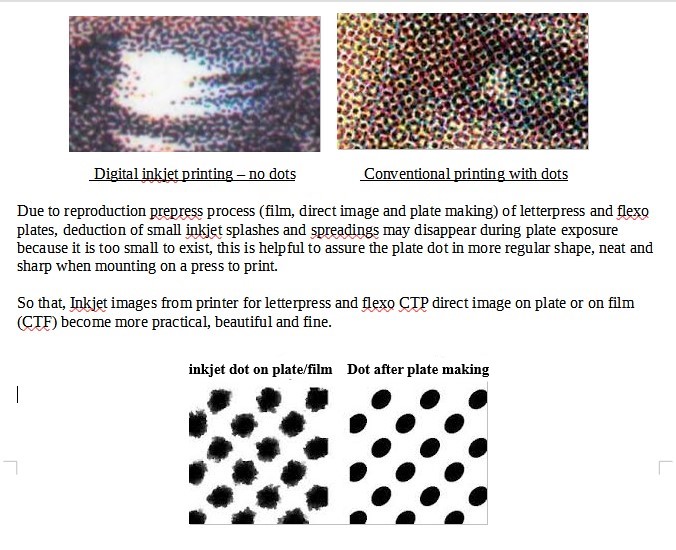

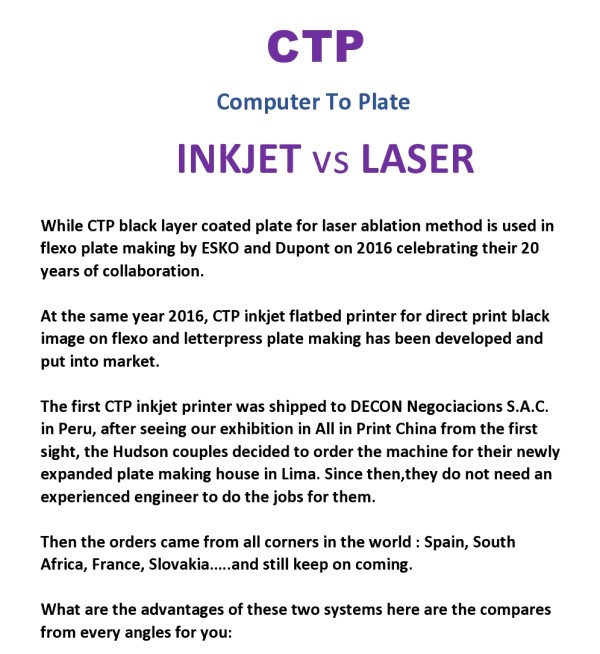

Prepress innovation after reaching perfect resolution good for all printing plate making by CTF (Computer To Film) inkjet images on special coated films, now same results to print direct on letterpress and flexographic plates for fine color flexible packaging, label and box printing is available now. This is due to new breaking through of nozzle technology with a flatbed printer able to print fine images on plate materials directly which means that no expensive digital plate and laser equipment are required for CTP (Computer To Plate) in printing industry any more.

To apply a black layer with an enough opaque black density on plate then use laser technology for fine image ablation in order for go through the UV light to cue the area for printing, this is the principle of a digital plate. First of all it is necessary for a machine to apply laser beam although it is not strong but still more expensive than an inkjet printer. Secondly, the plate needs to have a black layer coating which means the cost is increased and not all plates are available with this coating for some users.

Meantime because of fine reproduction is now possible, this is also a good news for screen printers especially for fine electronic circuit industry (PCB), CTS (Computer To Screen) will be an ideal choice of reproduction the plate without film, vacuum and exposure, these functions now are all can be done at the same time by equipping together with a LED/UV lamp inline the printer for sharper image, less labor, time saving and reducing wastes due to failures during the process.

FTA

FLEXO TECHNICAL ASSOCIATION

for more information about plate making in your plant please visit:

http://www.flexotech.com.tw/en/ProductShow.asp?ID=256

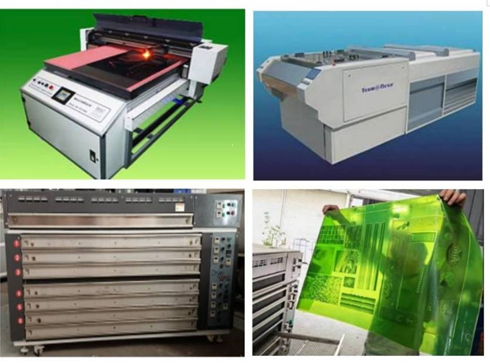

CTF→CTP→CTS

Keep on development and creation with

total solution and technology service

45 years in flexographic prepress field (since 1974), started from flexo and letterpress plate making consumable and equipment, from small to big, from liquid photopolymer FlexoBag to solid plate, from solvent washout to water washable, from negative film to plate materials. Flexo Technology based in Taipei Taiwan has gained reputation in the global market as well as keep on developing and creating new method, new applications for flexographic industry.

LaserBlack-easy negative making

LaserBlack Enhancer was the first idea and product before inkjet printer was not using so popular at beginning period of 21 century. At that time laser printer was commonly used as a print our instrument as well as it was the most clean and clear image can be printed for art workers after layout for film reproduction by using process camera. The laser prints on film was not opaque enough for plate exposures due to the particles of toner was not fine enough to array closely enough in order to avoid the gap in between when show up the image.

The enhancer actually is a simple coating machine to apply an even layer upon the laser printed material by using a water based solution to melt the toners over the print and the image will not spread out with no or very less dot gain but gaining the black density x3 up to 4.50 optically measured by transmission densitometer. This was the most cost economic way of negative making from consumable and equipment sides for every office was using laser printer to print their documents at that time.

LaserBlack Enhancer was so widely used in the decade over the world only the size was limited to A4 and A3 because there was not so many bigger size laser printer in the market even if have it the price was so expensive that nobody will buy it to make film. Customer’s demand for the big size film made us to keep on researching the inkjet printer with ink and film for use economically and in substitution of photographic film which is apparently will disappear in the earth soon.

CTF - as goog as photo film for repeat use

Due to experiences with laser enhancing system fortunately it is easy for us to develop new methods of film making by inkjet printer as long as we can find proper printer, proper ink, proper film and proper software able to RIP the dot precisely and to do the color separation job by only a click without experienced engineer any more. Thanks to the technical innovation, new inkjet printers with finer reproduction and less cost effective investment to make film by inkjet printer as good as a photo film from an image setter and the cost is less than a photo film. The dream is coming true.

CTP - no film plate making

To follow up a victory and press the attack, CTF (Computer To Film) is well accepted for the printing industry to make film good for plate exposure.

Now we are thinking far more than this. To think of using no film, no vacuum. We have to concentrate much more on making image directly on plate (any plate), we are now able to print image upon the plate directly for no film, no vacuum exposure to prevent failure of plate making to the less.

For this purpose CTP (Computer To Plate) system by inkjet printer, dream is also come true, digital plate is not necessary and expensive laser ablation machine is not requiring any more, any kind of plates can be printed with direct image on it. Furthermore by using new technology of LED, a UV lamp can be also equipped on the nozzle head of the printer to expose the plate simultaneously to cure the polymer or to harden the surface for no vacuum exposure protectively this is especially helpful to the big plate making.

CTS - no vacuum, no exposure

It is always a big problem of vacuum with frame when screen plate making. CTP direct image upon plate can be also used for screen plate making as it is emulsion coated. Besides the frame thickness of one to two inch which is difficult to do the vacuum well during exposure, if the air bubble in the middle between or vacuum power is not strong enough, it will fail and have to repeat again. More over screen printers know which kind of emulsion is good for what kind of ink to do the right job. In addition to this CTS (Computer To Screen) system with direct image, LED / UV exposure in line (no film / no vacuum / no exposure any more), it is also not necessary to change the emulsion you are using in order to prevent printer’s trouble of selecting proper solvent critically if the emulsion is changed.

CTF, CTP and CTS are new innovative developments of our team in these years. CTF is now able to make films up to 175 lpi dot reproduction and the quality is as excellent as photo film good for offset, label and flexible package printing. CTP flatbed printer is now made up to 64 x 110 inch (1626 x 2800 mm) jumbo plate making for huge corrugated box printing for motor cycle package. While CTS printer is now not only good for big screen frame direct image but also able to inkjet images on many small frames at the same time with UV exposure ready for developing and plate making as long as the frames can be put on the flatbed.

PPD BROUSSE Clichés

Ales / France

Ales is a village in France full with grape yards, about 120 kilo meters away from the beautiful city in south France of Marselle port. PPD BROUSSE Clichés is a traditional flexographic plate making house since 40 years ago. Mr. Daniel Brousse is the boss and his son Michael Brousse is the operation manager.

Daniel’s brother in law is running a corrugated box factory providing boxes for all grapes and wines, therefore they have to rely independently on them to make flexographic plate for printing jobs. The mother started to make the plate from design / art work / film making……. since 80’s. Now Michael has to work hard in order to provide plate making service of the box factories for all the city / village near around. Fortunately, now they have this CTP direct image printer to help them for the busy and tight production.

Before having this CTP inkjet printer, they used an inkjet printer to make film which is not necessary for them to invest extra money on a camera, processor and related equipment by using photo film which will no longer exist soon. This experience is helping them a lot and has make them to get acquaintance with operating this inkjet CTP printer for direct image on flexographic plate quickly and easily.

After the installation of hardware and inputting the RIP software into their computer as well as entering to their in house operating system. The next day, Michael starts to print images on the plate directly without using film. The UV lamps are equipped with the CTP printer under the flatbed for plate back exposure which is convenient for them no need to turn over the plate in the room which is not big, as well as the LED / UV on the inkjet head hardening the surface of the plate immediate right after print protecting any possible damage of image from moving the plate to washout processor which is not quite close and when a plate is not small.

Satisfactorily, they are all happy about the performance of hardware and enjoying so many choice of settings from the RIP software, besides of no film / no vacuum / sharp Image and easy operation, take all the advantages when the shop is not in a big space, not so many operators and processor is not in a nearby place for the big size plate making.

Michael is delighted personally because of this printer of no film, no vacuum and no turning over side of back exposure in line, will save him 15-20 minutes of processing time each big plate. Now he is not afraid of more jobs come in for he can handle it easily with this machine which means that he is able to enjoy finishing every weekend with his families now.

JUMBO FLEXO PREPRESS SYSTEM

NO FILM / EASY HANDLE / SHARP IMAGE

GIANT PLATE MAKING ESPECIALLY FOR CORRUGATED BOX

52 x 110 inch (1320 x 2800 mm)

64 x 110 inch (1626 x 2800 mm)

Team@flexo is now able to supply you Jumbo CTP inkjet printer in 52 x 110 inch (1320 x 2800 mm) by using no film / no vacuum technology which enable plate making to be very simple, easy and convenient for handling these jumbo flexo plate available in the world now. By just think of how to make the big film / how to move and draw down with plate by vacuum / how to check and how to escape the air bubbles in the middle of the film and plate, you will know how much the benefits of this Jumbo printer can do for you.

This will equipped with UV lamps under flatbed for back exposure on the printer in line. LED /UV on printer head access simultaneously right after print, in order to protect image on plate surface of no damage during moving for enhanced exposure and moving the big plate to washout machine.

Furthermore, plate manufacturers can make giant plate up to 64 x 110 inch (1626x 2800 mm) under special order basis, this is also no problem for NozzleBlack CTP printer at all. Only the actual effective back exposure area is limited to 52 x 110 inch (1320 x 2800mm) due to limited lamp length. Because, we use a best printer for X-axis from Japan which actually is a printer good for 64 inch print in width.

The jumbo film is not necessary any more due to direct image on plate now and no more vacuum during exposure of no film. Meantime, jumbo plate washout have also to be managed at the same time, in order to complete the whole plate making process. Fortunately we also available jumbo automatic washout processor with Auto washout + Exposure + Drying + Solvent recovery to finish total plate making steps.

Auto washout unit equipped with black ink / layer removing first then going into the normal wash department as for digital plate. Elevated exposure unit for post exposure and enhancing the fine line / fine text / fine dot exposure for 100% reproduction because of sharp image from direct image on plate. Drying unit equipped with anti-tack UVC treatment and a recovery unit is connecting fresh solvent come in and old solvent go out automatically.

This combination of corrugated flexo jumbo plate pre-press system is the most simple / easy / economic / low investment / low production cost / less damage / less failure / less labor ways of flexo plate making in the world by now. Just think of how much money can be saved from jumbo film making / jumbo film procession / jumbo plate moving / jumbo plate handling….., these is already saving a lot of money for you already.

DO YOU NEED A CLEAR IMAGE WITH NO COST OF FILM ???

NozzleBlack CTP printer

under CE inspections

How to do next when photographic film disappears?

The first few wave of rumors in the past that photographic film manufacturers will announce to stop manufacturing as well as photographic film is about to terminate the production and disappear again recently. For printing and plate making industry how to respond it, how to choose alternative plan to face this problem for future production requirement?

This is the way to provide for your choice:

CTP (Computer To Plate) no film imaging technology is a direct inkjet imaging on the plate, the latest technology. This image inkjet directly on plate can omit the film, and because of direct imaging, film and plate are “Zero” distance in between, so that the image is very sharp and can save the vacuum suction process (especially the screen frames) and the plate handling trouble and damage (especially when the large plate). Required material is only Inkjet ink, do not have to use film, can reduce lot of cost also eliminates the need for a lot of steps, operators can also be more rapid operation to reduce operating time. The principle is to move the printer on a flatbed, any plate just put on the bed then can print the image, the time of printing is the same as on the film. The flatbed can equip with UV lamp for direct plate exposure. Not only IR (infrared) lamp can put on the head section of printer to dry up the ink, but also add LED / UV to do exposure right after image print. This second option is current a hot item for corrugated printing plate and screen plate making industries. Their future is not afraid of the disappearance of photosensitive film.

The first inkjet CTP + LED/uv flexo flatbed printer

in the world

First corrugated plate making inkjet CTP ever

Printers => flexo plate making in plant

In the past days over the world or even in Japan now, most of corrugated printers (95%) are outsourcing their plate for they may presume that plate making is a total different production for a box printing company.

Now a days, they found the profit of outsourcing plate is taken so much from them that many corrugated factories are getting interest in making their own plates in plant from which may reduce this part of cost to only 10-20 % from what they are paying every month.

They may think of complications of first, film making then plate making, to hire more people for this purpose, no easy to have skilled engineers for the job. Most important is considering if there is a SOP to success the plate making. After they buying the equipment may just increase they capital investment and cause other problems of people management.

Obviously to save cost of everything inside the manufacturing factory is a trend for every industry now. Less people to work in plate making room with contemporary equipment of digitalization and automation by investing less cost machine for future production, this dream of 80-90% cost saving of your plate can come true.

Due to trade war between countries, JP corrugated box factories are predicting a recession is coming soon, for this reason, they have to cut off the high cost items and put into first innovation list. Changing from outsourcing plates to make it in plant is almost the first consideration and decision now so as the same way of thinking in Korea.

CTP (Computer To Plate), direct image without using film by inkjet printer is a first choice of economic investment for plate making now a days. With automatic washout machine for SOP process. Both are good and important weapons for digitalization and automation as well as for less cost effective investments. Two persons are required in the plate making room, and raw material cost is also limited to the photopolymer plate in boxes only.

Flexo prepress trend of post DRUPA16

CTP + Platemaking total solution

Hilson Huang – CEO / Flexo Technology Inc.

Future development of flexo prepress post 2016 DRUPA can be sniffed out new direction after the show, conventional flexo plate making both in technical and equipment sides have been considered to combining software and hardware together to receipt new era of digital technology, DRUPA 16 has clearly stated the trend of flexo prepress especially for the corrugated printing industry.

Remembered a few years ago, the

using of inkjet printer for printing industry is still in the stage of being

suspected , whether CTF inkjet film can completely replace photographic film

concerns four years ago, or even two years ago. Inkjet negative film can it be

compatible with photosensitive film? Inkjet film can it be completely replace

the photographic film industry and accepted by the industry? These questions

now jump from the CTF directly for flexo CTP application.

Offset CTP digital technology is

the use of image can be processed and

controlled by infrared (IR laser) or ultraviolet light (VIOLET laser).

Flexographic CTP laser device is already using almost the same principle, the

use of laser beams to ablate the image on a black layer coated photopolymer

plate surface, then following with hardening and washout of all platemaking

process steps. For such surface black coated plates user must pay a higher cost

of 20% -30% to the conventional plate.

During these well-developed

lithographic CTP 20 years, another new inkjet imaging technology was invented

in the United States and carried forward by the JP manufacturers ,as well as

with early application for advertising industry of molding cutters, nowadays

inkjet printer can print beautiful color jobs, then from small to large size,

from slow to fast production, from roll to flatbed, plus automatic demands of

feeding and delivery devices, the largest and fastest inkjet printing machine

has suddenly become a digital printing press.

inkjet printer and software within these 10 years, users like the inkjet printer very much, bigger and sophisticated equipment with more humane operation considerations, reduce the probability of failure and down time, more use making more user’s confidence. On the other hand because of more usage of inkjet printer more common senses such as training / maintenance / repairing are also becoming popular, users accepted both equipment and technology enhancing each other, the more inkjet printer contributed to the development of today's hot use.

Frequently answered questions (CTP / FAQ)

1. How NozzleBlack CTP inkjet printer was created?

Since LaserBlack enhance has created by Flexo Technology Inc. in 2006, we have about 20000 units used all over the world satisfactorily, some of the users are requesting for a new method to make bigger size negative film with good enough black density as LaserBlack enhancer.

After it, there are so many CTF system to print on film in the market with special ink and special treated film as negative for photopolymer plate making.

@flexo RD team was thinking more than that: a new technology can print on any untreated film as long as it is a transparent substrate in order to substitute photo film. In addition, to be able to print image on photopolymer plate directly with no film / no vacuum for 100% successful jobs and labor / cost saving.

Due to can print on any untreated film, therefore it is also can print on any surface of the photopolymer plate as well as on the screen frame, therefore the CTP inkjet printer was born in 2014, which is 8 years after the birth of LaserBlack.

2. What are the advantages to use NozzleBlack CTP inkjet printer?

a. Use any conventional photopolymer plates for our CTP printer, no more Digital plates.

b. No film cost only cost of ink.

c. No vacuum, no dirty spot, no air bubble and no more failure.

d. No turn-over for back exposure.

e. LED-UV exposure right after print to cure and harden the surface of plate.

f. Good for high speed production of platemaking up to 12-15m2 each working

day of 8 hours.

3. How is the resolution and density from a NozzleBlack CTP inkjet printer?

The opaque density is 3.50 which is good enough for any platemaking and as good as a photo film from an image setter with chemical developing processor.

4. Is the black image will fade / disappear and afraid of water?

The black image printed of negative area is dry up immediately after an IR lamp blow with hot air which will never fade away and disappear.

Due to use eco-solvent ink the image is not solved by water.

5. Shall we use special ink for NozzleBlack CTP inkjet printer?

Yes, NozzleBlack CTP black ink is a super-black nano ink with a very thin layer to reduce the cost of ink consumption but still keep a high black opaque density to block the UV light during exposure.

6. How about ink consumption and print speed of a NozzleBlack CTP inkjet printer?

Ink consumption of our CTP is 13-20 ml per m2 printing depends on the black area of image to print.

Print speed is 1 – 3.5 m2 per hour i.e. 17 - 60 min. per m2 depends on the RIP settings.

7. How about the fine resolution can we achieve?

Color separation and screening jobs can be done by RIP software recommended by us. Fine screen dot can be done up to 85 lines per inch which is good enough for corrugated box printing and screen printing.

Skilled engineers are not required any more for color separation / dot shape / ruling / angle all can be set by RIP software from your PC.

8. Any toxic or hazardous chemical used on the ink.

Ink and cleaner are eco-solvent products environmentally green and friendly which contents non-toxic and not harmful chemicals.

9. What kind of working spot shall we need?

An air-conditioned room is good for this precision printer which is making film and making plate at the same time for you, needs a clean, cool and dry place to work.

10. Where can we buy the ink? Any shipping problem?

Ink and cleaner are packed in a ink pack of 200ml are available from us and our dealer, which can print 10-17 m2 of black image, if for your job of 40 m2 each day, suggest to use 2 packs every day.

Cleaner is consumed not so much only when cleaning the nozzle head normally. When force cleaning the channel and head it will used a little bit more of cleaner.

Please note. Other ink and cleaner are not recommended for our printer to prevent block and damage of printer head.

11. Do we need to use digital plate for NozzleBlack CTP inkjet printer?

For NozzleBlack CTP inkjet printer it is not necessary to use digital plate (with black coating), by just using conventional flexo plate is good enough and much economic for your platemaking cost.

12. After print, how to take off black ink to prevent pollution of washout chemical?

a. It is easy to take black print away after exposure by a vinyl tape just stick and pull.

b. To wash off by solvent first before washout the plate.

c. New generation processor to wash off the black ink at first tank as for digital plate is required for an auto-washout machine.

13. Can we use any other ink to print?

No, you can not use any other ink and cleaner for the channel and nozzle head make be blocked and damaged easy. Meantime your warranty also may be discontinued.

14. Black ink will dry quickly right after print?

Yes, we have an IR lamp acting as a heater with hot air for drying up the ink quickly to prevent ink spread in order to keep fine image and dot area clean and clear.

15. Can we use any plate and film to print?

Any conventional photopolymer plates can be used for direct CTP image on plate which will save a lot of labors, costs and time for you. At the same time, any transparent film without treatment can be printed as negative film on the flatbed as well.

16. What plate making else can we do with this NozzleBlack CTP inkjet printer?

In addition to print on all kinds of photopolymer plate (for corrugated flexo printing), the printer is designed for the height up to 100mm therefore it is also good for a screen frame to insert under the x-axis of our printer for direct image and UV exposure inline at the same time. (CTS computer To Screen)

17. Shall we adjust NozzleBlack CTP inkjet printer frequently?

As mentioned the CTP printer will clean the nozzle head frequently and automatically, once you have set up the conditions and running smooth according to your production, it is not necessary to readjust the printer at all.

18. How about warranty for you?

One year of warranty from Team@flexo except nozzle head. (as all printer manufacturer’s guaranty.)

Using of any ink and cleaner other than Team@flexo product will be also exempt from our warranty.

19. Any tips to print fine and quickly for my plate making?

A. Always to print following instruction and training from our engineers. Do not use any ink and cleaner other than our products which will block ink channel and damage nozzle head.

B. CTP printer will clean frequently and automatically, which will keep the head in best condition to print.

C. Paying more attention to ink and cleaner to see if it is enough for your daily job for mass production.

20. Any other suggestions from you to use this CTP for our mass production?

Please note the bigger the plate the easy for this CTP plate making to save your labor

No need to turn over the plate for back exposure and no vacuum for no failure.

For your production under 10 m2 / each day we have good efficiency and economic Model: NB-1080.

For mass production of 30 m2 / each day we have a high speed high performance 2nd generation 3matic printer for you with only a very little additive cost.

Model: CTP 1550-4260 and CTP 1550-5280.

21. How about ink consumption and cost.

The only consumptions are ink and cleaner:

13-20 ml per m2 black print depends on image area and settings of dpi / pass / dot size ….

Cleaners will be only used when it is auto-cleaning or charge-cleaning which is not much.

Both ink and cleaner are supplied in a 200ml pack for good protection of quality and never dry up.

Price are USD 50.- / pack of ink USD 15.- / pack of cleaner.

In case of any more query, please do not hesitate to let us know. We will be happy to answer all the questions for you.

NEW DEVELOPED FLEXO PREPRESS AUTOMATION

WITH WATER WASHOUT SYSTEM

PLEASE VIEW VCD DEMO from our

CTP-噴墨成像+UV+背面曝光 - Flexo Inkjet Prepress Technology CTP inkjet image on flexo plate - Flexo Inkjet Prepress Technology (flexoNozzleBlack CTP-175 vs CONVENTIONAL DOTS

TOUCH PANEL CONTROL - AUTO WASHOUT UNIT

PLC touch panel it is easy and clear to control the washout machine with solvent temperature control and solvent

density checking device automatic release used solvent and replenish, the new fresh solvent with black layer removing washout tank for inkjet CTP and digital plate. All solvent contacted compartment we use all stainless steel for rust free.

DRYER + ANTI-TACK + POST EXPOSURE UNIT

UVC lamps for anti-tack treatment and UVA lamps for post exposure 3 levels of dryer with 3 temperature controls with 3 timers individually.

SOLVENT RECOVERY UNIT

Fresh solvent from recovery unit sucked into washout unit automatically

NozzleBlack digital direct inkjet – Flexo CTP

In May 2012 during Drupa, a new technology of digital inkjet printing press was shown and have been commended as an great innovation after Mr. Johannes Gutenberg had invented a printing press. As a matter of fact it was derived from electronic image forming by a liquid electro-ink method in 1993 during IPEX, by taking advantages of magnetic field reaction to form an image roller then transfer onto paper or substrate.

After 20 years, direct image to photopolymer plate by inkjet printer – CTP INKJET for flexo plate making without using film is also becoming practical and practical.

Actually, it was an extensive development of CTF (Computer To Film). Due to new development of Nano ink technology, CTP (Computer To Plate) INKJECT is now practical, ordinary, economic and substantial with more versatility of wider range for substrate selection. NozzleBlack can inkjet to any untreated film and uncoated paper

as tracing paper which is a cheapest translucent paper material for negative making as a film. Ton May 14-17 2013, CTP INKJET for photopolymer plate making was announced in China Print by which opening a new era of Flexo CTP.

Conventional photographic film manufacturers have announced to terminate the production, this has scared most of the users, film price increase day by day thus has forced consumers to pursue other methods in stead. Due to Nano technology, to prepare a color dye of 20 nano is no longer difficult now, plus additives for the ink, it is easy to have a ink layer by inkjet at 40-50 nano and reaching the same density of offset ink layer which is 400-500 nano, however the consumption of ink is only 10% does not matter it is an ink layer of color reflection or black opaque to block the light transmission when forming the plate image. This is the reason why we can use the ink to spray image directly on the photopolymer plates, no mater it’s a letterpress plate or flexographic plate in any thickness with any brands.

Specialty of nano-ink

Nano-ink can absorb more lights and reflecting more than regular an inks so that the reproduction dot is showing sharper, slippery, even and shining in order to reflect more colorful areas of YMCK with 15% more color than offset printing ink layers. This is the specialty of nano-ink which is reducing ink absorbed by substrate to shine up colorfully.

Moreover, with thinner layer of nano-ink inkjet printers can spray at higher speed, no mater it is a coated or uncoated surface, film or paper with no coagulation or spreading or even on any photopolymer material which is available on the market.

Flexo plate making

IN-PLANT why?

No matter you are a label / flexible packaging / corrugated box flexo printer, it is important and necessary to have your plates made at yourown factory.

This is nothing to do with money, but it will grant you ten advantages as below:

A. Time saving

B. Waiting time saving

C. Transportation saving

D. Quality controllable

E. Complete line for high production

F. RD for new future.

G. Cost saving 80% than our sourcing

H. Use new equipment and technology for low capital investment.

I. Keeping your own business secrete and customers secretes.

J. No more digital plates use your conventional plate.

When you are out sourcing for plate making outside the factory it will be time for sending / waiting for production / delivery back to your plant. The quickest maybe 1 day – next day delivery but in many areas it will take at least 1 week or even more. In some case may have to go out side the country then sending back to you which may take 2 weeks to 1 month.

These time waiting may lose interest of customer keeping on giving you printing order or even go to your competitors who are doing in their own plant will make delivery quicker than you. In addition, time waiting will also affect your printing productivity and cash flow.

Now a days it is easy to send a file by internet or other tools but still after plate is made has to deliver back to you. The quicker the delivery, the higher the cost of transportation fees. In-plant plate making will delete all these costs for you.

As printing press foot print is so important for not only the press but also for each of color printing units therefore it is very free and easy for you to calibrate each printing unit in your factory and adjust it from your own plate making conveniently. So as to the improving of your printing quality as you like just inside your own plate making room.

Normally a boss knows how to buy a good machine for the production, but a smart boss will also think of it is important to build up a prepress room by using the new developed technology and equipment for capital investment saving and more efficient. By which to complete the full production line in plant completely.

For RD purpose (Research and Development) is also an advantaged way of thinking for a factory. May sometimes also getting grants from government authorities. But it is easy and convenient for your prepress room to conduct new projects for your own future. A clever boss may give extra bonus to encourage employees for creating a new product or project.

Many bosses told us that after having their own plate making in plant have saved their out sourcing cost a lot, up most to 80% saving if compare with it is in the past with our sourcing expenses. Bosses are quite happy for the new technology, innovative equipment and application soft wares provided in whole package. As well as earn all advantages mentions here.

New technology means NO-FILM innovation for the future, digitalization makes dream of no film come true for sharper image and film cost saving. For the new equipment a CTP (Computer To Plate) inkjet printer to print a black image on plate directly then to exposure with no film and no vacuum device is now upside down the tradition with low capital investment of inkjet printers.

Most important is keep privacy of you and your clients’ secrete, many printers do not want to leak source of their job in order to protect their business. And your clients also do not like their competitors to know what they are doing now as well as what they will do in the future from the packages you are printing for their future products.

There will be a major saving for using conventional plate you are using is good enough for you to keep on your production smooth, due to not necessary to use particular digital plates for our inkjet CTP, you do not have to change to use plate other than your favor for the best printing result you are requiring. You just use the plates you are normally use.The price difference for a digital plate is about 30% higher.

FLEXO TECHNOLOGY INC. (FTI) HAS THE ABILITY AND RESPONSIBILITY TO HELP YOU BUILD UP YOUR OWN PLATE MAKING IN-PLANT WITH ADVANCED EQUIPMENT, NEW TECHNOLOGY AND SOFTWARE OF LOWEST CAPITAL INVESTMENT BUT HIGH PRODUCTION WITH HIGH QUALITY.

CTP Inkjet = Nozzle technology

NozzleBlack CTP inkjet is using a spray head with 2 sets for YMCK each for color printing in total of 8 nozzles. For negative image spray we use only K ink in black color, Depends on the ink, once the opaque is no good enough then we suggest to use 2 nozzles to spray K ink at the same time, thus will assure the black optical density over 3.50 which is excellent enough during plate making in order to black out the UVA lights and keep image sharp despite of it is a rough image or fine image. The other 6 nozzles can be spared for future use.

Advantages of CTP Inkjet

˙ Nano-ink

with nano dye and additives can allow ink drying quickly on non-treated substrates, the cost is cheaper than UV based ink and no UV curing device is required so as to a very expensive laser image ablator, which is saving a lot from hard wares.

˙ Ink saving

Comparing with offset printing ink layer the CTP inkjet ink layer is only 10% in thickness which means that can save a lot of ink not only in quantity but also in cost and cost of transportation.

˙Energy saving

No UV curing or extra drying unit is necessary when using nano ink, therefore saving energy a lot, after inkjet only a small bulb after the nozzle will drying the ink quick this will also reduce the problem of nozzle blocking.

˙Reducing costs

Use no more photographic film therefore the film cost is reduced, Due to use of nono ink a A2 sized plate will use only 4 cc of black ink able to achieve optical density over 3.50. Do not have to use any Digital plate which is about 30-40% cost up than a conventional photopolymer plate.

˙Any substrates

Wide range of substrates can be used and no special treating or coating is required therefore, can inkjet on any letterpress plate, flexographic plate, water wash flexo plate as well as for liquid photopolymer plate making. RD team finds that direct image on film for liquid resin spreading can be also sprayed in order for resin contact directly to the image with 0-distance. This has solved no-sharp-reproduction problem from the beginning of liquid photopolymer plate making had been created and invented.

Conclusion

NozzleBlack CTP inkjet for no film plate making is not using a special printer which is the same with printers in the market but we have paid more attention to the parts of:

fine reproduction, easy access, less breakdown as well as reasonable hard ware cost so that it can be accepted by the industry easily no mater how big is the size required.

This is quit different from a kind of small size A2 machine in the market now only good for thickness less than 2.30mm from which the market is divided.

In summarizing, a new era of CTP inkjet for flexo plate making is opening right after the China Print show in 2013, as Jessica Harkins reported on the Flexo magazine there is a wide array of people will make up the flexographic industry. Business owners, design partners, creative brains, old-school fundamentalists, young techs and everyone in between will work together to make our specialized industry stronger. NozzleBlack is expecting here the flower blossom.

SAY GOOD-BYE TO FILM TOTALLY

CTP FOR COMPUTER TO PLATE MAKING

Thanks to the new nano technology, ink opaque density over 4.50 now can print image directly on photopolymer

plate and screen frame which means that no more vacuum process during plate making thus will make film and

plate contacted completely with zero distance and no more air bubble problem which is a major failure of plate

making .

In addition to 100% successful job ,high density reaching 4.50 can achieve a good exposure result easily even for very

small dot for flexo or a fine detail on screen frame for electronic industry requirement opening a new era.