CTP Digital image on flexo plate

CTP Digital image on flexo plate CTP laser for color label

CTP laser for color label CTF Digital inkjet film making

CTF Digital inkjet film making CTF 175 / 133 / 85 lpi dot

CTF 175 / 133 / 85 lpi dot CTS digital image on screen

CTS digital image on screen LaserBlack- black film enhancer

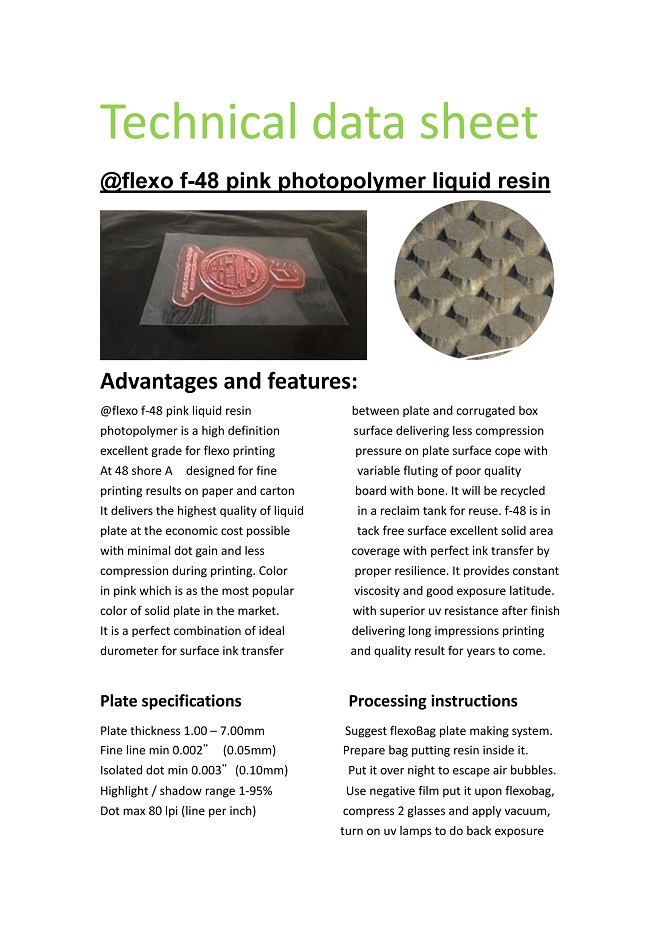

LaserBlack- black film enhancer @flexo liquid plate making

@flexo liquid plate making @flexo plate making machine

@flexo plate making machine Model: EZ (Easy type)

Model: EZ (Easy type) Model:A4/A3/A2

Model:A4/A3/A2 2436/3040/4050/4260

2436/3040/4050/4260 New automatic washout m/c

New automatic washout m/c Clean & wash after printing

Clean & wash after printing Stamp Making

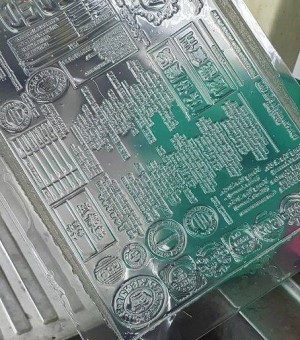

Stamp Making Photopolymer plates

Photopolymer plates Letterpress plates

Letterpress plates Flexo plates (solvent wash)

Flexo plates (solvent wash) Water wash flexo plates

Water wash flexo plates Digital photopolymer plates

Digital photopolymer plates Liquid photopolymer resins

Liquid photopolymer resins For cup.can.tube.pad printing

For cup.can.tube.pad printing For block print

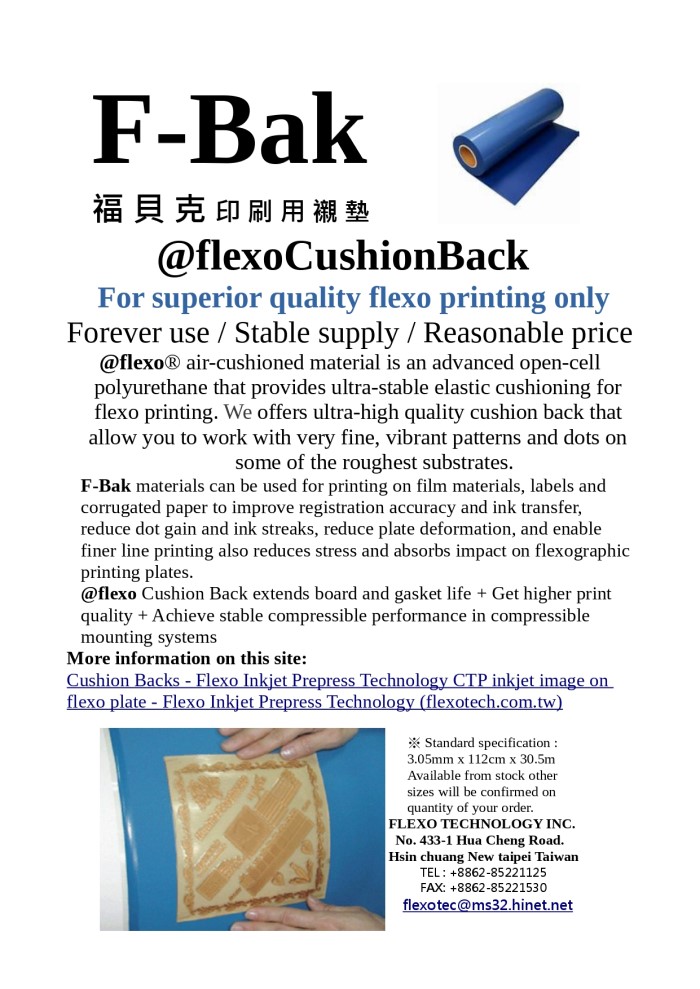

For block print Cushion Backs = F-Bak

Cushion Backs = F-Bak Double-side tapes for printing

Double-side tapes for printing In plant plate making

In plant plate making

View Big Picture

View Big Picture

FlexoBag DVD Demonstrations:

Pandemic help and support

Water wash / Simple / Easy

Fast / Low cost / No pollution / No mess

Use flexoBag system instead !

Rubber plate hand engraving technician is rather getting old in the corrugated box printing industry as well as no more young man will learn this skill all over the world.

In order for solving this problem and helpful for the box printers, the new flexoBag technology of liquid plate making with contemporary discovery of polymer synthetic engineering make the process with only water, no more use solvent in order to keep everything green and lower cost for printing.

flexoBag is an unique technic with invention / patent over 50 countries including USA and EU (EPC) by Flexo Technology Inc. By using bag to load the liquid resin, put it over night to remove the air bubble then flexoBag can be used as a solid flexo plate to do exposures right the way and by water washout after drying in 20 minutes can stick on press for immediate printing. (Not like solvent washed plates have to lay down flat overnight in order for solvent go inside the image area get dry completely for no image inflation during printing.)

Modern materials and new recipes of photopolymer is discovered and created after

trying and evaluations for the purpose of reducing resin manufacturing procedure and cost as well as from the progressing synthetic technology. Fortunately it has been proved to succeed in this issue of reducing about 50% of production cost comparing with the old stage photopolymer resins. In addition to this the resolution of fine line / text / dot is now as good as the old expensive resins and ink transfer in the solid area is marvellous due to softer durometers.

Furthermore due to flexo plate in a bag concept, machine for liquid plate making is no longer like a miniature plate coating factory any more, a simple designed unit for double side UV exposure at the same time can do anti-tack treatment is good enough for the process, other units like washout / drying / post exposure are remaining the same as the solid plate processor to save repurchase investments. Most important is the cost of equipment is not expensive any more.

Many corrugated box printers in CN and in SE Asia countries enjoying this system very much due to the advantages indicated above. For detailed information please view this site :

flexoBag system to make a plate in 20minutes

Most economic way to make film and plate for box printers

PLEASE VIEW VCD DEMO from our ON-LIN

E EXHIBITION :

ONLY WAY FOR HIGH QUALITY CORRUGATED BOARD PRINTING

NO MATTER HOW ROUGH and TOUGH IS THE SURFACE

F-Bak 福 貝 克 印 刷 用 襯 墊 @flexoCushionBack For superior quality flexo printing only Forever use / Stable supply / Reasonable price @flexo® air-cushioned material is an advanced open-cell polyurethane that provides ultra-stable elastic cushioning for flexo printing. We offers ultra-high quality cushion back that allow you to work with very fine, vibrant patterns and dots on some of the roughest substrates. F-Bak materials can be used for printing on film materials, labels and corrugated paper to improve registration accuracy and ink transfer, reduce dot gain and ink streaks, reduce plate deformation, and enable finer line printing also reduces stress and absorbs impact on flexographic printing plates. @flexo Cushion Back extends board and gasket life + Get higher print quality + Achieve stable compressible performance in compressible mounting systems More information on this site: Cushion Backs - Flexo Inkjet Prepress Technology CTP inkjet image on flexo plate - Flexo Inkjet Prepress Technology (flexotech.com.tw) ※ Standard specification : 3.05mm x 112cm x 30.5m Available from stock other sizes will be confirmed on quantity of your order. FLEXO TECHNOLOGY INC. No. 433-1 Hua Cheng Road. Hsin chuang New taipei Taiwan TEL : +8862-85221125 FAX: +8862-85221530 flexotec@ms32.hinet.net

<span style="font-family:" font-size:16px;color:#003399;"="">

flexoBag cutting the bag after exposure

flexoBag pear off upper bag film and mount on washout plate

EU patent in 40 countries

List of EPC countries

(Europen Patent Convention of 40 countries) (150608)

NO. | ENGLISH | CHINESE | CODE | NO. | ENGLISH | CHINESE | CODE |

1 | Austria | 奧地利 | AT | 21 | Luxembourg | 盧森堡 | LU |

2 | Belgium | 比利時 | BE | 22 | Latvia | 拉脫維亞 | LV |

3 | Bulgaria | 保加利亞 | BG | 23 | Monaco | 摩納哥 | MC |

4 | Switzerland | 瑞士 | CH | 24 | Netherlands | 荷蘭 | NL |

5 | Cyprus | 賽普勒斯 | CY | 25 | Poland | 波蘭 | PL |

6 | Czech Republic | 捷克共和國 | CZ | 26 | Portugal | 葡萄牙 | PT |

7 | Germany | 德國 | DE | 27 | Romania | 羅馬尼亞 | RO |

8 | Denmark | 丹麥 | DK | 28 | Sweden | 瑞典 | SE |

9 | Estonia | 愛沙尼亞 | EE | 29 | Slovenia | 斯洛維尼亞 | SI |

10 | Spain | 西班牙 | ES | 30 | Slovakia | 斯洛伐克 | SK |

11 | Finland | 芬蘭 | FI | 31 | Turkey | 土耳其 | TR |

12 | France | 法國 | FR | 32 | Malta | 馬爾他 | MT |

13 | United Kingdom | 英國 | GB | 33 | Norway | 挪威 | NO |

14 | Hellenic | 希臘 | GR | 34 | Croatia | 克羅埃西亞 | HR |

15 | Hungary | 匈牙利 | HU | 35 | San Marino | 聖瑪利諾 | SM |

16 | Ireland | 愛爾蘭 | IE | 36 | Yugoslav | 馬其頓 | MK |

17 | Iceland | 冰島 | IS | 37 | Albania | 阿爾巴尼亞 | AL |

18 | Italy | 義大利 | IT | 38 | Serbia | 塞爾維亞 | RS |

19 | Liechtenstein | 列支敦斯登 | LI | 39 | Bosnia | 波士尼亞 | BA |

20 | Lithuania | 立陶宛 | LT | 40 | Montenegro | 蒙特內哥羅 | ME |

LIQUID PHOTOPOLYMER SPECIALIST

F-90 photo resin

Liquidpolymer@matrix

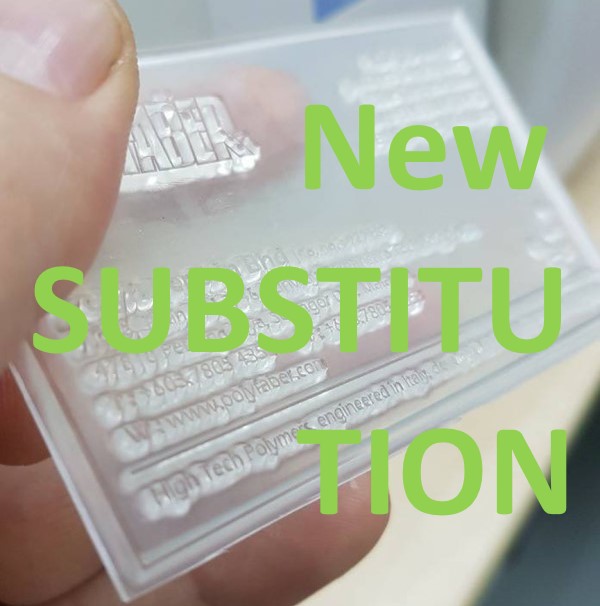

@flexogroup is announcing a new product of F-90 liquid photopolymer resin which is good for casting / molding / casting industries and rubber stamp / plate making as a plate for matrix making. Low cost, water wash, easy operation and economic equipment capital investment are the merits. By only preparing a can of F-90, you can make hardness of 90 Shore A (32 Shore D) and heat resistance of 180 degree C to make any size mold or matrix plates you like in depth of 5mm.

Solid plate for matrix is getting less will disappear soon and the cost of it is higher and higher. By using liquid photopolymer the cost is only 30% of a solid photopolymer matrix plate. In addition, no more acid etching of metal plate in order to improve our environment green of no pollution. Due to new invention and innovation, from LaserBlack now you can have negative to make a plate quickly from your laser printer also due to @stampBag patented liquid photopolymer plate making new method, now it is very easy to make a plate in plant for molding, matrix or printing.

LaserBlack enhancer can make a negative by your own HP laser printer print on tracing paper or transparent film, go through our Enhancer then after drying it you will have a very black negative on hand in your plant for all of any plate exposure. www.laserblack.net

By an innovative concept of putting resin into a bag to pre-move the bubbles to save your processing time, @stampBag is a total new solution for you to make a plate from liquid photo resin quick, easy with clean hands. The equipment is available from A4 size to A3 and any bigger size as you wish for mass production.

Compacted 4 in 1 design table top plate making machine for liquid photopolymer matrix plate

Machine including: Exposure / washout / drying / anti-tack complete functions in one unit

Innovative matrix plate

Advantages and features

Liquid Polymer Matrix Plate Making

Compacted 4 in 1 design table top plate making machine for liquid photopolymer matrix plate.

Machine including: Exposure / washout / drying / anti-tack complete functions in one unit.

Enable simple / easy / quick / convenient / clean operations for liquid matrix plate making.

Free thickness, any size as you like to make matrix plate in your plant quick and economically.

Don’t have to prepare lots of different thickness and size photopolymer plate in your stock.

Using base film good for back exposure and easy cut to size not difficult as metal based plate.

Any gauge matrix plate up to 7 mm at low cost as you like. No more expensive metal etching.

UV curing to harden the image and washout only by water green and no pollution any more.

Excellent heat conduction and transfer clear image. Base film heat resistance 190 degree C.

Cost is only 1/3 of photopolymer matrix plate. Product quality is perfect enough to replace.

Cost is only 1/3 of photopolymer matrix plate. Product quality is perfect enough to replace.

How to do when MATRIX PLATE is out of market

YOUR SMART CHOICE INSTEAD

Liquid photopolymer matrix plate

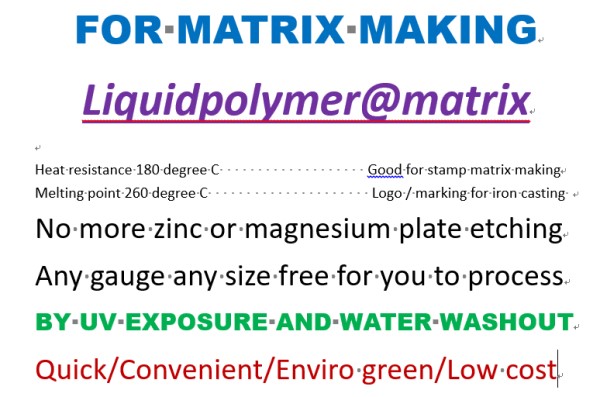

FOR MATRIX MAKING

Liquidpolymer@matrix

Heat resistance 180 degree C Good for stamp matrix making

Melting point 260 degree C Logo / marking for iron casting

No more zinc or magnesium plate etching

Any gauge any size free for you to process

BY UV EXPOSURE AND WATER WASHOUT

Quick / Convenient / Environment green / Low cost

Flexo plate making revolution

Simple + Easy + Green + Economic + Low investment

Water wash @flexoBag Plate Making System

Now invention granted worldwide, it is a revolution and new trend of flexo plate making system especially for

corrugated printing industry. Keep you far away from toxic solvent and lead you to a green environment.

Plate size : ( Available with CTF to make film)

Model 1000 : 700 x 1000 mm Model 1200 : 1000 x 1200 mm

30 minutes to make a plate (one shift for 10-20 square meters)

Making negative film from your printer + liquid polymer in bag low cost plate

= plate making is quick low equipment cost

◎Both LaserBlack & FlexoBag are registered trade marks in USA

FLEXO Plate making total solution for healthy and environmental-green printing

@flexoBag plate making system

Patents granted over 30 countries in the world

Liquid / water wash / low cost / fast process

◎Exposure +Treatment (GT)

Double side exposure+anti tack treatment unti with high intensity lamps good for fine dot reproduction.whole

processing time is only 40 minutes which is 50-30% of making a solide plate or a conventional liquid plate.

Available models :

FB2840 28 x 40in (70 x100cm)

FB4050 40 x 50in (100 x120cm)

◎Washout + Drying (WD)

Flat water washout with recirculation and filtration +Drying unit (WD) with built in water heating, circulating and filtration sustem with sticky mounting during washout-no double side tape required.

◎Bag Sealing (BS)

By suing hot seal material without sacrificing tight registration, FlexoBag now is possible to us this Bag Seal unit (BS) by which will reduce bag preparation within 3-5 minute which is a great time saving.

◎Bag Filling (BF)

By suing compressed air it is easy to input liquid resin into the bag, there is a formula for you to know how much resin has to put in for the purpose of accurate quantity for 3 dimensions of the bag.The bag then move to Bubble remover (BR) for air bubble to disappear and exposure ready for plate making process.

◎Bubble Removing (BR)

An innovative and rational technology to solve bubble problem off-line, short time and in advance before

procession. Whole processing time to make a FlexoBag plate is only 20-30 minutes, The total cost is only 50-60% of making a solvent plate.

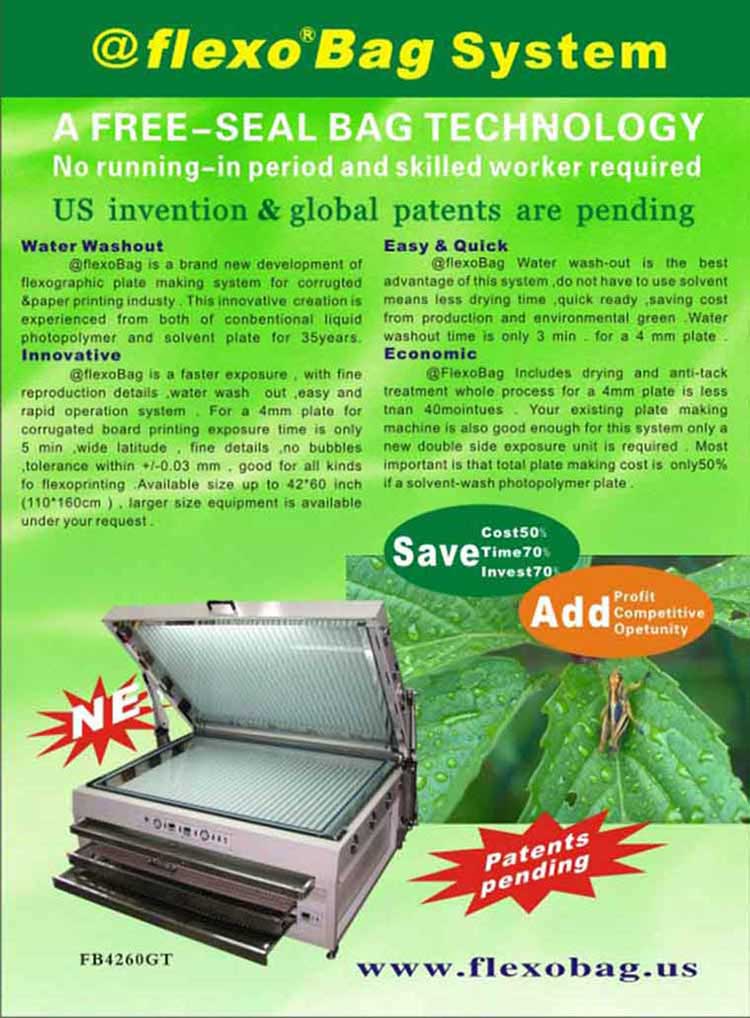

@flexoBag System

A FREE-SEAL BAG TECHNOLOGY

No running-in period and skilled worker required

US invention & global patents are pending

Water washout

@flexoBag is a brand new development of flexographic plate making system for corrugated & paper printing industy This innovative creating is experienced from both of conbentional liquid photopolymer. And salvent plate for 35 years.

Innovative

@flexoBag is a taster exposure with fine reproduction details water wash out easy and rapid operation system .for a 4mm plate for corrugated board printing exposure time is only 5 min. wide attitude fine details no bubbles

tolerance within +/- 0.03 mm. good for all kinds to flexoprinting available size up to 42x60 inch (110 x 160cm). lager size equipment is available under your request.

Easy & Quick

@flexoBag water wash-out is the best advantage of this system. Do not have to use solvent means less drying time. Quick ready saving cost form production and envitonmental green. water washout time is only 3 min – for a 4mm plate.

Economic

@flexoBag includes drying and anti-tack treatment ohole process for a 4 mm plate is less than 40 mointues. Your existing plate making machine is also good enough for this system only a new double side exposure unit is required most important is that total plate making cost is only 50% if a solvent-wash photopolymer plate.

A new solution to substitute Engraving plates

@flexoBag System

For liquid flexo plate making

(WATER WASHOUT)

Healthy you

Healthy life

Healthy printing

Corrugated plates for bright future

Questions and Answers (FB / Q&A)

FlexoBag liquid plate making

1. How flexoBag liquid system is developed?

Since LaserBlack enhance has been created by Flexo Technology Inc. in 2006, we have about 20000 units used all over the world satisfactorily, some of the users want to make big plate for corrugated flexo printing with water washout liquid photopolymer in addition to stamp making by using LaserBlack enhanced to make negative film / paper for economic and practical production reasons.

By using this LaserBlack + flexoBag system, most of corrugated box printers are very satisfied with this economic system, they are paying only 10% of the cost which was relied on out sourcing. In addition to pay extra money, they have to wait and wait for the delivery. But now they can make a plate in 10 minutes including negative and plate making which increased lot of efficiency in production for printing.

Meantime, flexoBag system is a creation from Flexo Technology Inc. headquarters in Taipei Taiwan with world patents over 50 countries including whole EU market. Because of water wash flexo plate making, the users are all happy with it for no more environmental problem and recycle equipment for them to invest for the wastes. They appreciate and enjoy the inventions of both flexoBag + LaserBlack from Tea@flexo very much.

2. What are the advantages to use flexoBag system for liquid flexo plate making?

a. Use liquid photopolymer resin which is the only way to washout by water without using toxic chemical and pollutions..

b. Put the resin in a bag is an good idea of quick processing because of no base film paving / resin pouring and spreading / cover film paving over the resin… these procedures will waste about 1 hour for a big plate to make. And sometimes the resin is still there which will make failure for the plate.

c. After filling the resin, the flexoBag is ready for plate making without any bubbles as a PS plate for offset printing, it is ready for film exposure immediately to make plates.

d. No more various stock of different thickness / size of plates which is also a big part of capital investment. Only buy liquid resin in KGs.

e. Team@flexo has total solution for you liquid flexo plate making including hardware and software / negative film and liquid resin / machine and supplies / installation and training.

f. Good for high speed production of platemaking 45 minutes to make a plate.

g. The capital investment is low for this unique new technology. No skilled engineer is required.

3. How is the resolution of liquid photopolymer?

The plate resolutions for dot is 85 lpi (line per inch) which is good enough for corrugated box plate making and printing .

4. Is the liquid plate afraid of water ink ?

Although photo resin is water washable, but after UV exposures and finishing, the plate is very strong and not afraid of water based ink and durable for printing.

5. can it be reused again after first printing?

Yes, after printing just clean off ink from the plate completely and dry it up, you can keep it as long as you like

6. Shall we use photopolymer resin only from you?

No, you may use any photopolymer resin as long as the quality is good. Resin supplied by us will remain the standard of plate quality and enjoy plate making after service from us.

7. How about resin consumption and other materials?

Depends on the thickness and size of plate you will make, we have a formula to calculate the consumption of resin as :

Plate thickness x 1 m2 = ?? kg resin consumption, for instance:

2.84mm plate x 1 m2 = 2.84 kg resin

3.94mm plate x 1 m2 = 3.94 kg resin

Other consumables are upper film and lower film to make bag to put in the resin. Upper film (UF) is a thin transparent film in order for negative film contacting to make sharp image. Lower film is a base film with special coating to stick with resin after UV exposure.

Both of films can heat melt together by a hot sealing unit to make a good bag to fill in resin without any leaking.

8. How many unit of machine for a flexoBag system?

The systems include these units:

@GT (Double-side exposure + anti-tack treatment unit)

@WD (Washout with recirculation & filtration + Drying unit)

@BS flexoBag Sealingunit to make bag

@BF flexoBag Fillingunit to fill resin

@BR flexoBag Bubble Removing unit to keep and escape bubbles inside the bag

Laser Black Enhancer A3

or buy NozzleBlack CTF printer for big negative making extra.

9. Any toxic or hazardous chemical used on the system.

All material including photo resin are environmentally green and friendly which contents non-toxic and not harmful chemicals.

10. What kind of working spot shall we need?

An air-conditioned room is good for this precision system which is making film and making plate at the same time for you, needs a clean, cool and dry place to work.

11. Where can we buy the supplies? Any shipping problem?

As mentioned, due to world patent flexoBag system with total solution, you can get the consumables from our dealer. Meantime, please rely on our supply of all the consumables such as photo-resin and bag films from us, shipping to every country is very convenient now if we have no dealer in your country.

12. Do we need skilled engineer to make plate?

No, after our installation and training, any unskilled operator can be a good engineer to make liquid plate from flexoBag system. We have good experiences in many countries that after our engineers’ training many corrugated box printer start in-plant plate making in 5 days after our engineers come back, they can make good plate for production and they are all new to make plate.

13. After printing, how to take off the ink?

Use the same cleaning agent (detergent) as you are using for washing the printing plate on printing machine or recommendation from the ink supplier how to clean the plate after printing,

Dry up completely so that you can keep it long.

14. Shall we put chemical into the washout water?

Yes, for better washout result, you have to add 1-2% of the detergent into wash water. This will also help to reduce the sticky problem with resin and bristle during washing, also to washout clean and clearly.

15. How long shall we wait to print after plate is made?

Unlike solvent washout plate, the solvent go into the plate deeply to solve the unhardened part and inflate the hardened part, so that have to dry up at least 1 to 2 hours to wait for plate drying up completely inside the image area by a hot air of 60 degree C in the dryer. (Waiting for the coming back to normal of inflation inside the plate.)

Photo resin plate use water to wash, water will not penetrate into center of the image but to wash off only the unhardened resin. The image will not inflate so can put on press to print immediately after plate is made.

16. What plate making else can we do with this flexoBag system?

We have many users use this system to mass production stamps, for actually flexo plate making is only an enlargement job of stamp making.

17. How about warranty from you?

One year of warranty from Team@flexo after installation and training

18. Tips to make plate quickly?

A. Always to prepare bags at fix size ready for quick use as PS plate.

B. Check and keep all consumables in proper stock to prevent running out of materials

19. Any other suggestions to flexoBag users?

A. To keep working area clean and neat is the basic demand to make a beautiful and clean plate.

B. Use rough brush to clean off resin residue in the center of brush everyday as well as clean the filter off when finish the job.

C. Clean up water in washout unit after work and keep it fry for using next day.

Thus will prolong the equipment life and make beautiful plate for you.

In case of any more query, please do not hesitate to let us know. We will be happy to answer all the questions for you.

www.flexotech.com.tw flexotec@ms32.hinet.net

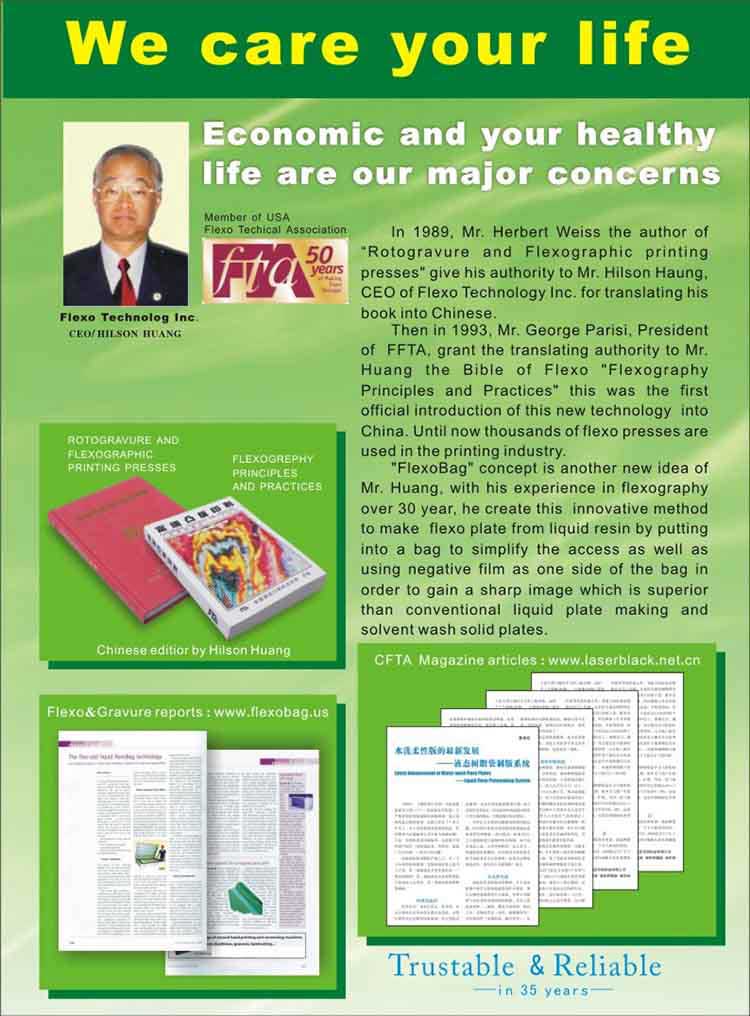

We care your life

Economic and your healthy life are our major concerns

In 1989. Mr. Herbert Wises the author of “Rotogravure and Flexographic printing presses” give his authority

to Mr. Hilson Haung. CEO of Flexo Technology Inc. for translaating his book into Chinese. Then in 1993. Mr. George Parisi, President of FFTA. Grant the translating authority to Mr. Huang the bible of Flexo “Flexography Principles and Practices” this was the first official introduction of this new technology into China. Until now thousands of flexo presses are used in the printing industry. “FlexoBag” concept is another new idea of Mr. Huang. With his experience in flexography over 30 year. He create this innovative method to make flexo plate from liquid resin by putting Into a bag to simplify the access as well as using negative film as one side of the bag in Order to gain a sharp image which is superior than conventional liquid plate making and solvent wash solid plates.

Flexo liquid photopolymer resins

Handing / Storage

Flexo liquid photopolymer resins should keep in a cool and dry place at 20-30 degree C and a relative humidity of approximately 60%. Also should be kept in a safe light area and resins must be protected from UV light when

operating under these condition the shelf life is 5-6 years.

No running-in period and skilled worker required For 35 years in package the company has been located in E-Land, the Eastern side of Taiwan –an isolated area before the freeway was built five years ago (June 2006), due to inconvenient transportation from Taipei city areas (which is on the North-west side of the island). In the past it took around 4 hours to get there –nowadays it's only about 40 minutes when taking the tunnel (about 13 kilometers/8 miles). DJ Cartons operates three printer slotters for multi-colour carton printing to cater for the demand for packaging in the Eastern areas like Hua Lien and TaiTung counties. Now they have the ability to expand their territory to the city areas ; in Taipei DJ Cartons has opened a liaison office to take the orders after their own in-plant platemaking system from @flexoBag had been started. In the past DJ Carons had to rely on tradeshops in Taipei to make the plates. They spent around TWD 150,000 a month which was not competitive. The total annual expenses for platemaking amounted to TWD 2,000,000; some TWD 8.00 per square inch (6.5 cm 2 ). Now that DJ Cartons has started @flexoBag system, the total cost has come down to only TWD 1.80 square inch, which also includes the costs for making the negative. Using the LaserBlack Enhancer this is a very economic and convenient way for making a negative : all that is needed is a HP laser printer. The owners-two brothers-are happy with this new system as it has reduced plate costs by 75%. In addition : There is waiting time for plate delivery and the cost of transportation from West to East ; originals already having been sent online, which is quick. Two ladies in the factory were assigned to be trained as operators for platemaking for two days. They joined the production immediately, although they have had no previous experience with platemaking. They are very happy with their waterwash @flexoBag system as they do not have to stand the bad smell of washout solvent which is also toxic. The two lady operators have achieved the goal of meeting the slogan No running-in period or skilled worker required. New weapon as a substitute for engraving plates

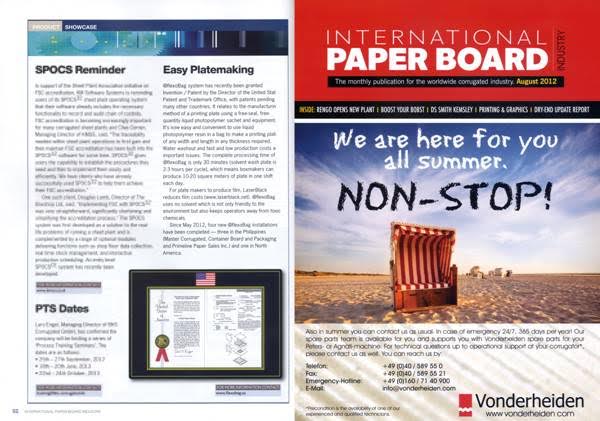

Nov. 14-17 2011 Flexo Technology had a successful exhibition in Shanghai at All-in-print China . LaserBlack Enhancer and @flexoBag System are our major innovative products at this show. Digital innovation has made less and less photographic film users (such as no-film, no-plate printing and CTP plate making). This has made existing photographic film manufacturer intending to increase their film price accordingly due to less and less consumptions. (50-80% increased this year). Therefore LaserBlack become a good alternative for plate makers, this probably because of over 10000 LaserBlack users in the world have proven its versatility. There are so many deals on the spot as we pushed an offer of SHOW SPECIAL during the show, many foreign visitors have enjoyed the same offer as well by taking away from the show ground. In combination, @flexoBag is a newly developed system by FTI with invention / patent which has been granted in many major countries already and pending in 40 countries over the world. Using water to washout / environmental green / quick and economic are the advantages of this system, the plate making cost is only 50-70% of solvent wash plate making also touching the heart of the bosses. Water washout is an important issue in flexo plate making nowadays and the whole processing time of @flexoBag is only 30 minutes in a cycle (solvent wash plate is 2-3 hours per cycle.) which means can make 10-20 square meters plate in one shift each day. (2 -3 boxes of solid plate.) For plate makers to make film, LaserBlack is another choice of photo film and reduce the film cost. ( www.laserblack.net ) While flexo plate makers especially for corrugated printing,@flexoBag use no solvent which is not only friendly to environment but also good to keep you and your employees away from toxic chemicals. ( www.flexobag.us ) Contact us immediately if you are interest in these innovative products.

|

Feedback from customer in South America |

Feedback from customer in South America Good day! I want to comment to you that we have been working very well all the time with flexo making plate you sold us since 2010 and also plates have a good quality and they are more flexible than former plates we had before. The HP 5200 A 3 printer which we have bought from you is working very well with your LaserBlack Enhancer which enable us to make our own negative film any time in our factory at very low cost and it is very convenient. As to the Model @A2SSF flexo plate making machine, which is also performs very nicely of all the functions : Exposure + Washout+ Drying + Anti-tack treatment 4 in 1. Due to all stainless steel made, it looks as new as the time we have bought it two years ago. This time I want ask you quote us sheet @flexo plates like last time. Please quote all goods price under C&F Arica, Chile in American dollars, we will take insurance from Taiwan to Bolivia, please do not don't worry about it although we know the freight maybe expensive, but we still like to buy from you.

We appreciate very much that only you can provide the total flexo plate making solution for our one-stop shopping requirement including: prepress + materials + plate + equipment in once and one shipment. Thank you once again and have a nice day. Best regards, Marcelo Lizarazu Orellana FIMAR LTDA. Tel: 591-2-5249985/5242613 Oruro , Bolivia . (110831)

Chang Yuen Paper packing Co. , Ltd. VN , Lo J1, duong NA3 – DA3 KCN My Phuoc II, Huyen Ben Cat Tinh Binh Duong , Vietnam Experiencing new @flexoBag plate making technology To whom it may concern: We are a corrugated paper company with 6 flexo printer /slotter in our factory, before we make our own plate in plant, we are paying about USD 2000.- of photopolymer plates each month from the trade shops near around. Besides this, we have 10 people making hand engrave plate and a laser engraving machine making rubber plates for not so fine image jobs. Due to growing business, the owners have decided to make our own plate in our plant. Photopolymer plate making is a brand new item for us, so we have started to search for new technology of equipment and materials in order to improve our printing quality as well as for expanding our future business. Eventually, we have found @flexoBag System is a brand new technical for photopolymer plate making to meet our requirements of low investment, quick process and environment green for us. The total equipment cost with consumables for initial starting cost us USD .- for a 60 x 90 cm size machine which is quite practical for our use and quick process of the system has increased a lot of our productivity. By the end of December 2010, we are expecting to have our investment return, for we have found the total cost of the production including everything is less than 20% of the plates we rely on trade shop before. The owners know that using this new system is worth with no regret now. Feedback from Indonesia PT PREMIER JAYA INDO JL RAYA PERTAMINA NO 8 SUMBERAME WRINGINANOM GRESIK INDONESIA

We are corrugated board company in Surabaya / Indonesia , due to labor wage increasing gradually and it is not easy to find skillful hand engraver to make rubber plate with many small letters on it, we must to find out a simple, easy economic and green way to make our own printing plate for printing the cartons in plant. Moreover, it is getting expensive for the plate we rely on trade house to make for us outside, so that we have to pay too much plate making fees every month, and it is becoming not a small sum as USD 20000.- annually. Therefore we start to search a good way to solve these problems for us and eventually we have found @flexoBag system from internet. The website is neat and clear enough to let us know everything about the new system with the DVD, the Q&A and the Feedbacks from their users by which we have found some of their users are in the very similar production situation with us. After having the comprehensive information, we have decided to place our order immediately in order to start up the plate making right after our New Year Holidays which is in the mid of September 2010. Two of @flexoBag engineers come from Taiwan at the beginning of October right after the machine had reached us and in 5 days, now we are able to make our own plate smoothly. Printers are happy because of no need to wait for plate delivery from trade shop any more or even have to go to collect the plate when we have to use it urgently.

I have to admit that we are not only happy with the @flexoBag system but also we have to thank them for their skillful and quick service offered to us to do training to our people for both plate making and for the machine maintenance. They are quite professional! Wenyao He - NGHIEP - CHIN CHIA PACKING & PRINTING FACTORY DONG-CHENG TOWN , DONG-GUAN CITY , GUANG-DONG , CHINA We are Chin Chia package printing company located in Dong Guan where is a major manufacturing city for all kind of goods export to most of the countries all over the world. Our job is making and printing film bags, paper bags and corrugated box supplying to the factories located in this area. At the beginning we use conventional flexo plate, but because of the green environmental requirement is getting higher and higher so that we have decided to find a more friendly method to make plates. We have made flexo plate by solvent washout for quite a long time, until it was a good chance for us to see this new announcement of water washout flexoBag system during DRUPA 2008 in Dusseldorf Germany, after the show we have made several visit to see the demonstration of how to make a bag, how to fill in the liquid resin, exposure, wash by water and request for making plates for our test printing on line to proof not only for the reproduction but also the long impression running of the plate made by the system for it is a brand new technology in the flexo printing industry. All of employees hate the strong solvent odor so much that we have to decide to use this water wash system as soon as possible. The solvent recovering department people, now they join us in printing room, for they have lost their job already. In addition to these, plate making room is no longer a dirty place like before any more. The happiest person should be our boss, not only for the production cost have been reduced 40-50% and processing time very short, most important is that the boss has returned all his investment back by now mostly because of using no solvent any more. In spring of 2009, we started to use @flexoBag plate making system, now we could not print without it for everybody love it, even our former plate making shop is using the same system following us. Pre press Dept. We are very happy and healthy with @flexoBag I am delighted to report that the @flexoBag system works well in our factory since July 2009. I made some excellent plates from liquid photopolymer by using the flexoBag system and use only water to wash it out, it is very incredible that the plate is the same quality with the solvent washout flexo plates. Now all the people in the prepress room are very happy with it because of no disgusting odor in the factory any more, every body looks very healthy now. Due to flexoBag can be prepared in advance before plate making, the bubbles are disappeared therefore it is very easy and quick (50% time consumption only) to use by just putting the film and bag in between two glasses do not have to pour in resin waiting for spreading and take off the bubbles on the machine, so the exposure process is now simple and easy for us in stead of the hard works of spreading the thin film and paving the base film (because the bubbles may happen again during this procedures). No spreader, no coater and no bubble happened, the machine is very simple so the cost of investments we have paid is only 30% of the conventional machine cost, plus the production cost is only 50% of the solvent wash flexo plates therefore we are expecting to have our return of investment quicker by June of 2010 definitely. All of our employees like this new flexoBag system very much

Hen Cog 22-27 Tienmu West Road Taipei , Taiwan @flexoBag on FLEXO Magazine Oct.2009 / FTA-USA ( e - book download many take few minutes )

@flexoBag system Photopolymer Liquid Resin An unique FREE-SEAL Sachet Technology

@flexoBag is a brand new development of flexographic plate making system for corrugated & paper printing Industry. This innovative creation is experienced from both of conventional liquid photopolymer and solvent plate for 30 years.

@flexoBag is faster exposure, with fine reproduction details, water wash-out, Easy and rapid operation system. For a 4 mm plate for corrugated board printing exposure time is only 5 min, wide latitude, fine details, no bubbles, tolerance within +/- 0.03mm, good for all kinds of flexo printing. Available size up to 42 x 60 inch (110 x 16cm), larger size equipment is available under your request.

@flexoBag includes drying and anti-tack treatment whole process for a 4 mm plate is less than 20 minutes. Your existing plate making machine is also good enough for this system, only a new double side exposure unit is required. Most important is that total plate making cost is only 50% of a solvent-wash photopolymer plate.

@flexoBag Water wash-out is the best advantage of this system, do not have to use solvent means less drying time, quick ready, saving cost from production and environmental green. Water washout time is only 3 min. for a 4 mm plate.

Quick / Easy / Green / Time & Labor saving / 50% cost down This new liquid technology is no bubble, wide latitude, good ink transfer, high resilience, abrasion resistance, fine resolution, tack-free, excellent shoulder support for long impressions as well as low production cost.

flexoBag system Sealing unit (BS) With instant and constart sealing results for the imago size you required, to avoid varidus stock for different gauges and dimensions.

Filling unit (BF) With high pressure air from your own air-compressor to fill in the photo-polymer resin to the bag with no bubble for immediate plate making.

Recovering unit (BR) With air-knife to clear off and collect the unhardened photopolymer in order for reuse, by this will also increase 10-20% of your production.

Models : @2436 (for plate size up to 24x36 inches = 60 x90 cm) @4260 (for plate size up to 42 x60 inches = 110 x 160 cm)

FREE – SEAL Sachet Technology Total solution includes :

Exposure unit – Double-side exposure + anti-tack treatment unit (GT) with high intensity lamps good for fine dot reproduction. With powerful air exhausting during anti-tack treatment.

Washout + Drying unit – Flat water washout with rrclrcrlation & filtration + Drying unit (WD) with built-in water heating, circulating and filtration system with sticky mounting during washout-

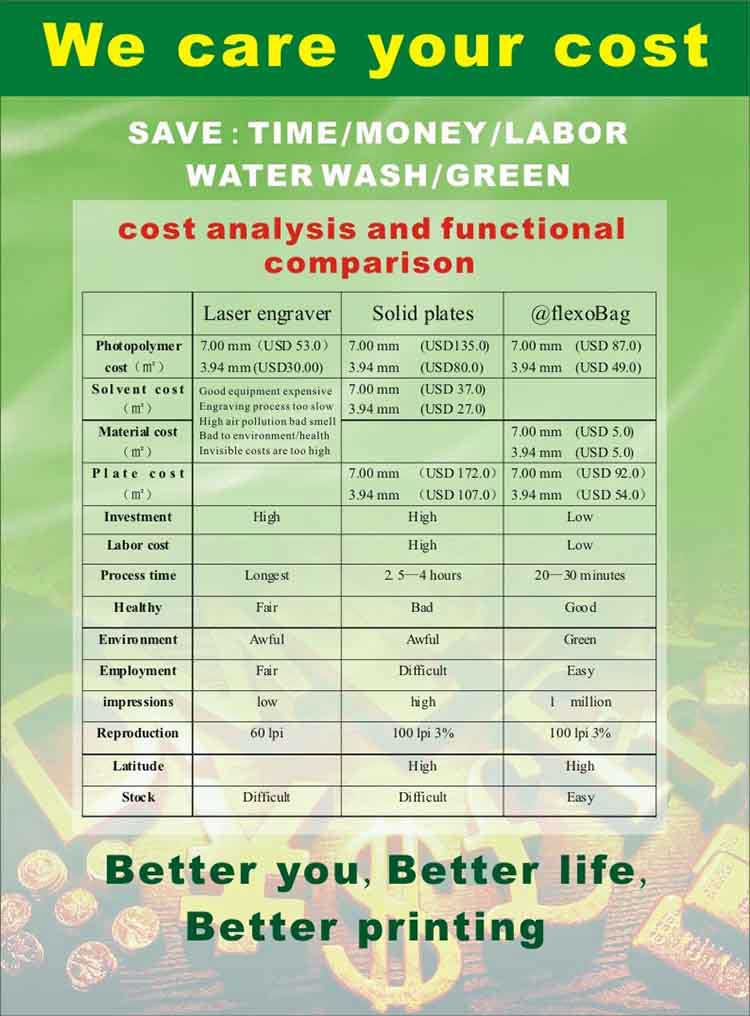

Model : FB 4260 GT Exposure + Treatment Unit @flexoBag System New weapon to substitute Engraving Plates A new solution to substitute engraving plates for corrugated board printing is now available from @flexoBag system which is a new weapon for the future business,the reasons are: • Good engraving machine is very expensive, however a low end machine and hand engraving can not satisfy the users anymore…..both trade shops and printers. • Engraving process is very slow and it is not easy to engrave it in fine detailed images, which can not meet the requirements of plate maker and printers. • Laser engraving companies odor smell as burning a rubber which is in high air pollution and bad to human health. • Environmental green is an important issue nowadays, odor smell, air pollution, and using of solvents are the trends to be avoid. While @flexoBag system is using a new patented technology to put liquid resin in a bag with free quantity and free seal to make a plate in any thickness and size according to your negative, the advantages are: • Water washout - Use water to washout the plate, no more solvent is required which all the plate makers are happy with it, the environment is clean and green now. • High productivity - Due to this new invention of @flexoBag, plate making is very quick now. To make 30 square meter of plates ( 4mm thickness) in 2 shifts each day is very simple and easy now. • Simple stock – No more complicated stocks of various thickness and size to stock the plate by just preparing a pail of liquid photopolymer resin in 18 kgs or 200 kgs drum. • Low investment – By using @flexoBag System the complete set of equipment investment is only 30 percent to a conventional liquid resin plate making machine. • Production cost is LOW –The production cost now is only 50% of a solid plate washout by solvent, for using water to washout the plate will save you solvent cost which is 20-30% of the plate cost • Employees are happy – Your employees will be happy with you wise decision for they will work under a green environment and healthy than ever before.

@flexoBag System Plate making tips @flexoBag liquid photopolymer plate • Storage:

• Unexposed resin pail

• Processed plate

• Handling:

• Preparing bags: • Make sure base film side with sticky back and mat side film is for keeping your plate surface smooth. • Seal together with heat sealer or tapes assure that no leak of the bag, especially double secure the 2 corners when the bag is very big.

• Filling resin: area from the bottom valve into the bag by a high-pressured air compressor. • Then keep the bag in a standing rack one by one in order to be ready for exposure with negative film.

• Exposure: • Due to resin already in the bag, therefore you may put the negative under the bag or upon the bag with no difference of plate making result. C. Total exposure time is 2-3 minute (4mm plate) ratio of back and film exposure time is depending on distance and kind of light source. D. You may cut off the 4 sides of the bag, now the plate (bag) is ready for washout.

• Washout:

• Drying

• Post-exposure

• Anti-tack exposure

• Press ready @flexo Bag Photopolymer

F-32 & F-40 for corrugated industry, F-50 for stamp making

@flexo Bag is a faster exposure, with fine reproduction details, water wash-out, easy and rapid operation. for a 4mm plate for corrugated board printing exposure time is only 5 min, wide latitude, fine details, no bubbles tolerance in + / - 0.03mm, good for all kinds of flexo printing. Now size available from A5 to A0. @flexo Bag Water wash-out is the best advantage of this system, no solvent means less drying time, quick ready as well as saving cost for plate making and environmental green. Water washout time is only 3 min. for a 4 mm plate. @flexo Bag Plus drying and anti-tack treatment whole process for a 4 mm plate is less than 20 min. Your existing plate making system is good enough for this system, only a new double side exposure unit is required. For more details please visit www.flexotech.com.tw. @flexoBag Plate Making Trouble Shootings • Bag making Bag can not be hot sealed Make sure materials are from @flexo Coating of bag edges have to be removed Temperature or timing of sea ling is not enough Bag leaking Coating take off is not complete Bag does not seal well enough Check time and temperature of sealer • Fil ling resin Resin too much Over the bag difficult to do exposure Resin too less Plate size will not enough or too thin Proper quantity Check from the operation manual • Bubble removing Bubble still there Bag does not stand square in 90 degree Bubble disappears too slow Use heater on the Bubble Remover • Back exposure Plate base is too thick Reduce the back exposure time Plate base is too thin Increase the back exposure time What is proper thickness of plate base 60% thickness as plate base is proper • Film exposure Plate not sharp a. Negative opaque density not enough Remake the negative or check again b. Exposure not proper Over exposure or under exposure Bubbles in between film and plate (try to escape the air.) c. Bag is becoming hard Negative film exposure is over d. Bag is becoming soft Negative film exposure is under e. Image looks dirty not clear Back exposure and Film exposure is not proper f. Some of image area disappeared Thickness control is not proper (Check the vacuum meter of the unit)

|

Celebration of 10000 units – extra gift sale |

Celebration of 10000 units – extra gift sale ON-LINE-SHOP SPECIAL LaserBlack International is celebrating 10000-units sell of their LaserBlack enhancer since first announcement at 2002 SGIA Show in Mississippi St. Louis USA . The black density enhancer is a simple idea to coat a solution all over a toner printed page which is printed on a tracing paper (vellum) or film by a laser printer. After drying the coated solution is melting the toner and become a black layer upon the image area without any diffusion so that opaque density is enhanced 300-400% which is good enough for any kinds of plate making and its as good as a photographic film or a film outputted from an image setter. This unique enhancer has been granted inventions / patents in 35 countries and has been exported to 65 countries including developed countries, developing countries and under developed countries. All the users are happy to have this simple and easy unit as their personal image setter, especially when it is very convenient and economic to make negative / positive film for label / news paper / screen / bag / corrugated board printing and stamp making. Now they are running a campaign of “ 10000-units celebration special” with extra gift for on-line shopping. All kits are including the enhancer A4 / A3, a Quick-Black dryer and 500CC of LaserBlack-Solution which can process 1000 sheets of A4 or 500 sheets of A3. Plus extra gift of 500CC to make it 1 liter now. |

No skilled worker required |

Two ladies in the factory were assigned for training as operator of plate making for 2 days and have to join the production immediately although they have no experience about plate making before, now they feel lucky to have water wash @flexoBag system for they do not to have to stand the bad smell of washout solvent which is also toxic. Two ladies they have achieved the goal as our slogan “No running-in period and skilled worker required.” (more…..) |

2011 Sino Corrugated Booth no. S-145 |

2011 Sino Corrugated Show will be held April 6-9 in Shanghai |

Washout unit with spray rinsing gun |

Water washout unit for letterpress / water wash flexo / liquid resin plates with aspray gun is veryconvenient for rinsing the plate after washout. With a 3-way valve for supplying fresh water one way to water tank now can be switched for rinsing the plate after washout. All @ flexo washout unit (except solvent washout) is equipped with this device to make plate making a real pleasure. |

Exposure unit with cooling system |

Air conditioned cooling vacuum board on exposure unit is equipped for both flexo and letterpressphotopolymer plate making equipment in order to achieve accurate stability of strict color registration jobs to combining with CTP process. @ flexo has supplied with their new generation of this high end exposure machine for both domestic users and have been exported to many countries to work with CTP machine forprosperous demands of digital plate market. A big Model 2001E+Air for plate making up to 110 x 205cm with this new facility has been installed in South Africa successfully, the user is proud of having this advanced unit for their digital plate making. |

Seminar of @flexoBag System |

Seminar of @flexoBag System was held during Tigax exhibition period in October 2010.

Hilson Huang, CEO of FTI is delivering a speech of @flexoBag system by presenting a DVD. |

2010 Flexographic Technical Innovation Award |

2010 Flexographic Technical Innovation Award sponsored by Flexo Technical Association / USA |

@flexo plate making machine now is available On Line |

New EZ serier A4 plate maker for economic cost and fast |

The 5000th Unit LaserBalck Enhancer Special Campaign ! |

Innovative negative making machine for all kind of plate making, |

Exhibition event for 2009 : SINO CORRUGATED / CHINA PRINT: |

Sino Corrugated : April 7 -10, Hall E5-Y160 Shanghai International Exhibition Center

|

Liquid photopolymer resins available now |

@flexo Liquid photolymer resin is now available in : F-32 / F-36 / F-40 and F-50 with any color you wish, which is in the durometers of 32 / 36 / 40 and 50 Shore A. F-32 is good for big solid area corrugated board printing with deep reverse line and character with excellent carriage of ink transferring to the rough surface of the board. F-40 is used for small and midium size character printing to reproduce the sharpness of image for corrugated board printing. Many color printers would rather like to use this durometer for color separation jobs with fine dots directly print on the surface of the corragated board. While F-36 is in durometer of 36 Shore A, which is in the middle of F-32 and F-40, people like to use this because of F-36 can print good solid with reverse image as well as it can print character and line works satisfactorily. F-50 is designed for stamp making at durometer of 50 A which is a very proper hardness for hand-stamp and any kind of self-ink stamp holders for long duration. All available resins are formulated by a contemporary recipe with new developed materials which are water washable and with UVA light finishing to cover up the sticky surface before process is finished.

|

@flexoBag plate making for corrugated printing |

@flexoBag System is a newly patented invetion of a FREE-SEAL sachet technology using liquid photopolymer resin and water washout to make photopolymer plate for paper / paper bag and corrugated board printing. The new concept is total different and up-side-down the conventional liquid resin plate making, due to it is in a bag, the machine is not so complicately required therefore a simple machine with economic cost is good enough for plate making, Bags can be prepared in advance to escape the bubbles according to the negative films. Equipment cost is only 30% of the vertical elevation conventional construction type eliminating also the coating part on the exposure machine to make it lower cost but with all functions, for these we have to thank of its resin-in-bag with one side open for free- seal, which means that you can make a bag and prepare the resin freely with no limitation of three dimensions and quantity of a bag. You can also make any thickness plate you like by just rely on the gauges surrounding the bag between the two glasses. |