CTP Digital image on flexo plate

CTP Digital image on flexo plate CTP laser for color label

CTP laser for color label CTF Digital inkjet film making

CTF Digital inkjet film making CTF 175 / 133 / 85 lpi dot

CTF 175 / 133 / 85 lpi dot CTS digital image on screen

CTS digital image on screen LaserBlack- black film enhancer

LaserBlack- black film enhancer @flexo liquid plate making

@flexo liquid plate making @flexo plate making machine

@flexo plate making machine Model: EZ (Easy type)

Model: EZ (Easy type) Model:A4/A3/A2

Model:A4/A3/A2 2436/3040/4050/4260

2436/3040/4050/4260 New automatic washout m/c

New automatic washout m/c Clean & wash after printing

Clean & wash after printing Stamp Making

Stamp Making Photopolymer plates

Photopolymer plates Letterpress plates

Letterpress plates Flexo plates (solvent wash)

Flexo plates (solvent wash) Water wash flexo plates

Water wash flexo plates Digital photopolymer plates

Digital photopolymer plates Liquid photopolymer resins

Liquid photopolymer resins For cup.can.tube.pad printing

For cup.can.tube.pad printing For block print

For block print Cushion Backs = F-Bak

Cushion Backs = F-Bak Double-side tapes for printing

Double-side tapes for printing In plant plate making

In plant plate making

View Big Picture

View Big Picture

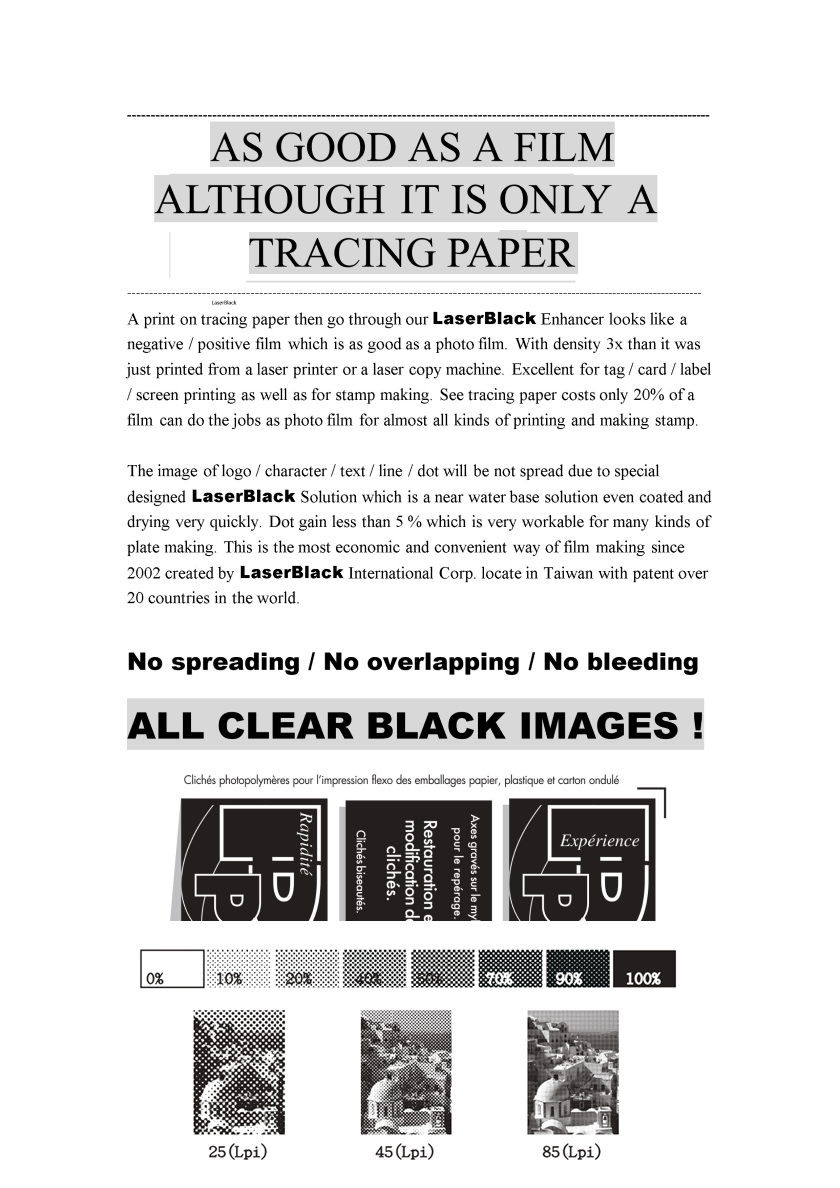

ECONOMIC AND QUICKEST FILM MAKING FOR PLATES

VIEW DVD demo from ON-LINE EXHIBITION first:

LaserBlack for Screen plate - Flexo Inkjet Prepress Technology CTP inkjet image on flexo plate - Flexo Inkjet Prepress Technology (flexotech.com.tw)

LaserBlack Enhancer

LaserBlack Enhancer has been granted invention patent in most countries of the world for over 10 years, but still it is a simplest / economic instrument for negative and positive film making ever now.

Photosensitive films are getting out of market, while inkjet film is not so wide accepted, for small jobs within A4 and A3 size as stamp, silk screen, card, label, corrugated box printing .....

LaserBlack Enhancers are acting as a most practical and money saving way for film making to be exposed with a plate for printing.

Pandemic help and support

DoubleBlack Systems

NozzleBlack + LaserBlack

Double Black for film making = LaserBlack (since 2002) + NozzleBlack (since 2014)

LaserBlack is a black density 3x enhancing method from a print by laser printer.

NozzleBlack is a direct image on flexo & screen plate from inkjet printer without film.

NozzleBlack CTP (Computer To flexographic Plate) is the only system direct image on a plate by inkjet printer in the world. Since 2014, 20000+ users over the global enjoying no film direct image on flexo plate as well as on a screen frame emulsion coated for no film / no vacuum. Can be exposed by an in line LED / UV on an inkjet printer for 100% successful job without failure, covenient with a very sharp image.

Due to print from a laser printer was a most clear / sharp image / with nice black density good for reproduction text / character in the past days. It is however, still not good opaque enough for plate exposure when print on a film or tracing paper by a laser printer.

LaserBlack enhancer was the product for plate making purpose from an image print out by a laser printer at that time. Convenient / economic / easy to operate was the slogan….. after laser print then go through LaserBlack enhancer to get 3 times black density to expose a plate nicely. We have twenty thousands of users in the global market and keep on growing until now due to cheap and convenient.

In addition to CTP direct inkjet image on a flexographic / letterpress plate, we also equipped in line on the inkjet printer with back exposure UV lamps under the flat bed for non-turn over relief exposure to save labor and damage. This was the advantaged technology we used with our 40 year-experience of manufacturing flexographic plate making machine so as to the usage of a LED/ UV lamp in line to harden the printed image right after inkjet print at the same time. This is also most important for CTS (Computer To Screen) because of no film / no vacuum will benefit screen plate making from more sharp image / time saving / no vacuum failure for repeat making any more as well as a skillful engineer is not required any longer.

With invention patent in 40 countries and 20000 users over the world, consumers still always complain that the printer is too small for them, for there is very few laser printer size over A3, this was the inventive of why Team@flexo have to develop inkjet printer for film making: CTF + CTP + CTS these 3 C actually become an important motives of Flexo Technology in the past 5 years to make a change to create a really applicable film making technology for plate makings. At the time while everybody is keen on CTF Computer To Film making we believe that we have the obligation to develop more advanced technologies of CTP / CTS for no film / no vacuum plate makings by inkjet printer for big size / good enough density negative film making which is a far cheaper method than to use an very expensive laser ablation device.

And fortunately, we have made it possible. (190505)

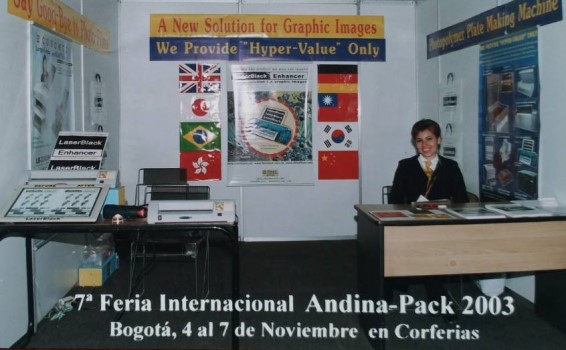

First announcement of LaserBlack Enhancer in Bogota / Columbia Andina-Pack 2003

Print ready film in minutes

A desktop system which allows the production of high density

Film from a laser printer, is available from Flexo Techonolgy Inc.

in Taiwan.

LaserBlack is claimed the first desktop film system to produce

Print-ready film in minutes without hazardous chemicals, no

Messy sprays and no costly equipment. LaserBlack enhances

Laser printed transparency by increasing image density,

making the output suitable for exposing silk screens or

photopolymer plates used in screen, letterpress and flexo printing.

Simply print your image from your desktop laser printer, then

Run it though the LaserBlack unit and dry it with the heat gun

You have just produced your first print-ready film, With LaserBlack

You can produce film positive or negatives quickly, easily and

Cheaply with an image density suitable for exposing all kinds of plate.

LaserBlack is a non-toxic, environment friendly chemical.

The film’s opaque density can reach or exceed 3.50, and results

Are as good with fine line characters and dots.

The company suggests that HP or Canon Laser Printers are used

For best results. One liter of LB-Solution can process 2,000

Sheets of A4 size tracing paper or transparent film.

SGIA

SPECIALTY GRAPHIC IMAGING ASSOCIATION

LaserBlack Enhancer

history

LaserBlack enhancer, the idea is very easy to think of and originally comes from alcohol to melt the black toner from a laser printed image on tracing paper or film then coating by a simple machine as a laminator. This easy and simple concept make Laserblack Enhancer able to be granted for a worldwide invention & patent over 20 countries in the world since 10 years ago.

At that time film making by an inkjet printer was not so popular and not so well accepted while photographic film is disappearing gradually. Sales including export broke 10000 units quickly in few years after putting into market although the size is limited to A4 and A3 size, but it is nice to make a positive / negative with black density enough tracing paper / film so economic and convenient for all kinds printing including letterpress, flexographic and screen printings including stamp making.

Hardware basically is designed according to the construct of a lamination machine, but due to alcohol is used as enhancing solution so we have to pay more attention to all parts should be resistant to strong solvent when it is necessary to use as a ingredient to solve the black toner evenly with no image spreading. It is also important for us to use carbonate fiber as raw material for the out case in order for long endurable and longtime using. Total parts used for this machine is over 50 pieces since we want the machine to be able to do minor adjustment of the different

gauges of tracing paper / film and do not want fine images and dots to expand.

Ever since the beginning of having this idea to make an excellent enhancer, at the design period from out looking and structure of the unit until the mold making for out case injection procession, the team of LaserBlack enhancer is proud of to make everything successful as expected and to achieve the goal of 10000 units sell quickly in such a short time.

FTA

FLEXO TECHNICAL ASSOCIATION

ALL DEVELOPMENTS START FROM LaserBlack

CTF→CTP→ CTS

LaserBlack Enhancer

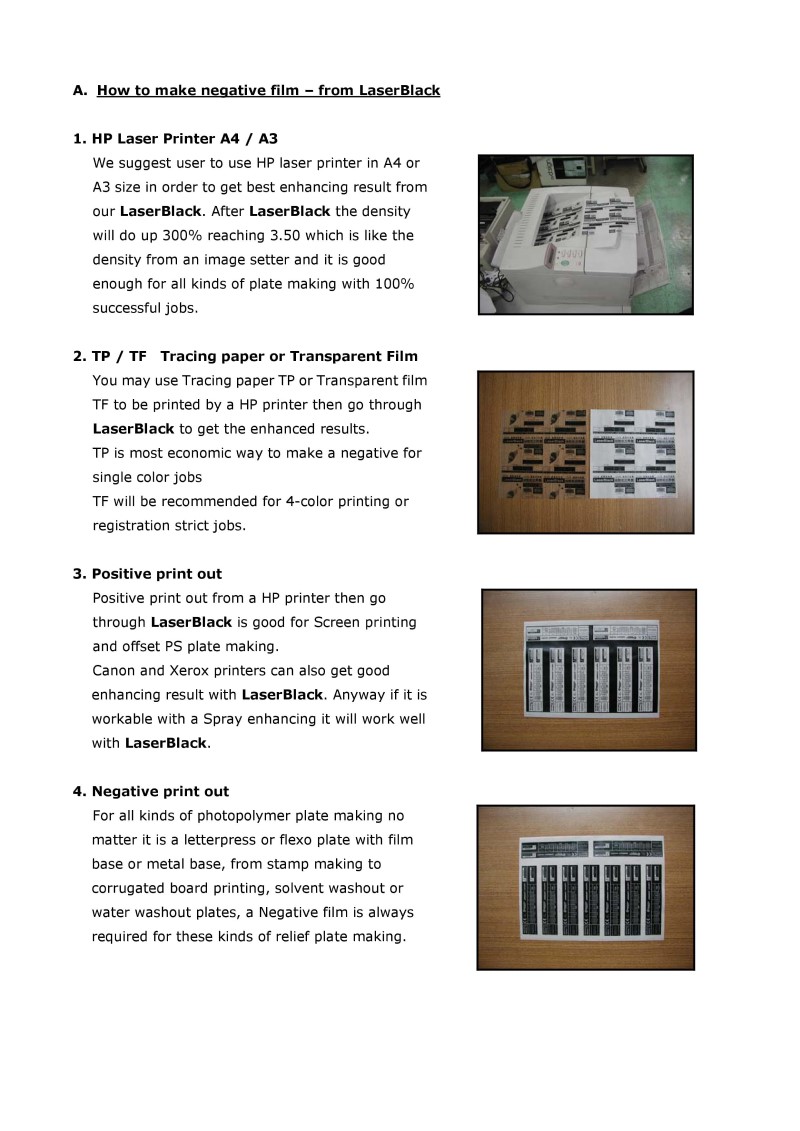

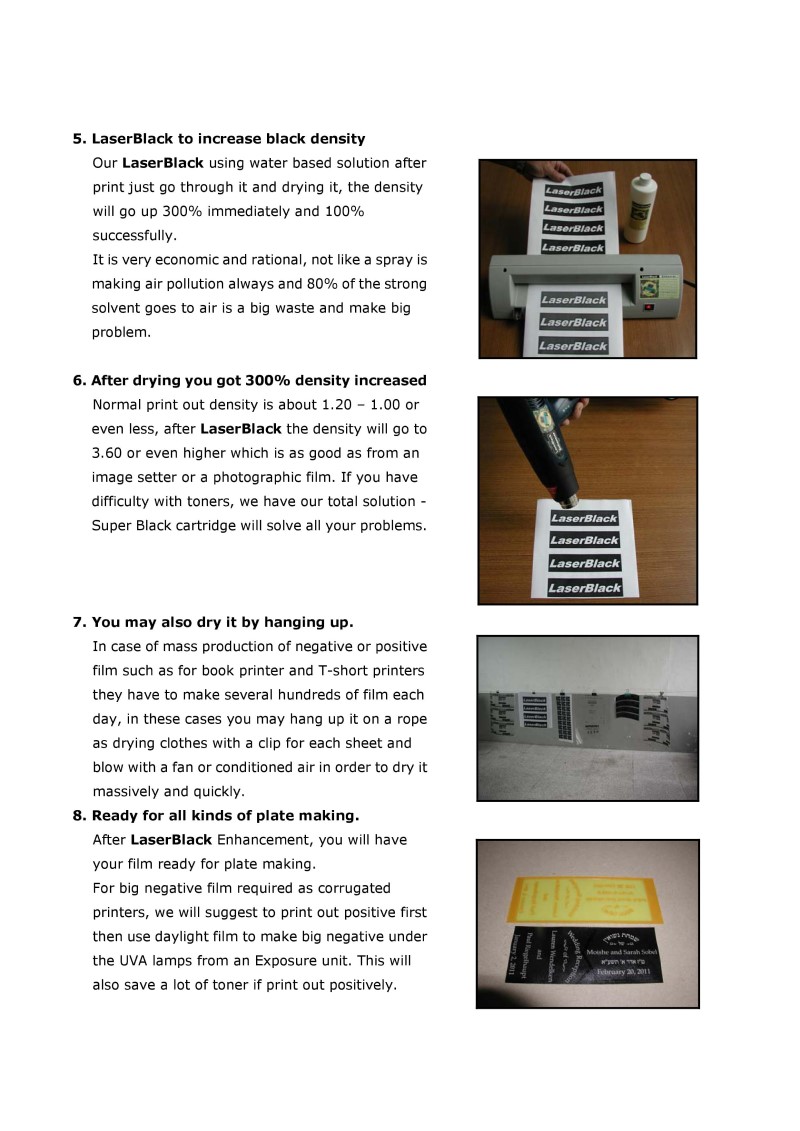

1. How is LaserBlack used?

Images on monitor, printed on translucent paper or transparent film by laser printer, then go through our LaserBlack Enhancer can get dark enough density as traditional photo film for exposing plate directly to make all kinds of printing plate. 2. How is the result of it?

No matter what you print, we can make it 300 to 400% darker.

The density can be high up to 3.0 to 4.0 (Depends on your printer). 3. Does it effects the blank areas?

LaserBlack is a clear solution, leaving no visible residue effecting the density in transparent areas. 4. Will it fix the toner image forever?

Yes, it will not only solve the toner evenly and stick on the surface forever but also will fill the gaps between the toner, it is really incredible. (See “feedback from users.” On our website) 5. Will it work on inkjet prints?

No, LaserBlack is designed for laserjet printers only. 6. How about consumption of LaserBlack solution?

A4 2000 sheets per liter, A3 1000 sheets per liter. 7. How about finest character and dot?

Character: 4 pt Dot: 150 lpi

It depends on your printer, no matter what you print, as long as you are satisfied with the print, we just make it 300 to 400% darker density for you to make a good plate.

New generation printers such as 1200 x 1200 dpi can get fine print so as to get better enhanced results absolutely. 8. Is it really non-toxic and no harm to human?

Yes, we use hi-tech non-toxic solution, not harmful to human. 9. Can I use inside the room?

Yes, you can use it inside the room, only suggest to open the door for venting. 10. Any shipping problem?

No, as we do not use strong and toxic solvent, there is no problem of shipment. 11. What is a proper material for printer?

As long as it is a translucent paper or transparent film can be printed with your laser printer which is good enough for our enhancer. However, if your requirement is critical, we will suggest you to use our paper or film to get best enhanced results for good registration for color printing. 12. After procession, is it really use water to clean off ?

After operation just wash off your hands with tap water. 13. Can I use any brand of laser printer?

Yes, but will suggest to use HP or Canon for best enhancing results. 14. Is the density anything to do with drying method?

Yes, each set of LB enhancer attached with a Quick-Black Gun, suggest to use this Q-B gun to get quick and best results. 15. Can I use recycle toner cartridge?

Of course you can use recycle toner cartridge, sometimes, the enhanced result is better than the original one. 16. What kind of printing plate making can be used?

All kinds of plate making need a positive or negative film to expose the image can use LaserBlack R System. Now the density can reach 3.0, so it is no problem even to expose the longest exposure needed as for 7mm photopolymer plate directly for corrugated board printing. 17. Shall I adjust the enhancer frequently?

No, once the enhancer has been set up, you will not need to adjust it any more.

Unless you want to adjust it for applying more or less solution. 18. How about warranty from you?

One year warranty and after service for long. 19. Any tips to reach more black density?

We have made several experiments in our laboratory, in order to get darkest density for some users making critical plates, please refer to the following chart:

It shows that if you lay down the paper 2-4 minutes after enhancing, then dry it with Q-B gun. The density can increase from 1.05 to 3.24 – 3.49, which means 309% to 332% black density increased. To put the enhanced paper aside for 2-4 minutes then drying it, you can get best enhanced results. 20. In addition to this, any other way to increase density?

To release the pressure between 2 rollers in order to carry more solution applying to paper surface, lay it down for 2-4 minutes then dry up will increase density definitely.

LaserBlack enhancer is a most economic and quick way to make a negative film on tracing paper or transparent film from your own HP laser printer the biggest size now is A3. In case of any query, please do not hesitate to contact us, we will be very happy to answer you all the questions.

21. If the black result is not so good what should we do?

Check if drying step is not complete / running out of toner in the cartridge / 100% black setting on your original file / using LaserBlack super black toner cartridge? www.flexotech.com.tw flexotec@ms32.hinet.net

VCD demonstrations:

http://www.flexotech.com.tw/ch/DownShow.asp?ID=58

http://www.flexotech.com.tw/ch/DownShow.asp?ID=60

<span style="font-size:14px;font-family:" color:#003399;"=""> http://www.flexotech.com.tw/ch/DownShow.asp?ID=59

Young brother of NozzleBlack

PLEASE VIEW VCD DEMO from our ON-LINE EXHIBITION :

http://www.flexotech.com.tw/en/DownShow.asp?ID=58

http://www.flexotech.com.tw/en/DownShow.asp?ID=59

http://www.flexotech.com.tw/en/DownShow.asp?ID=60

Your image setter

100% successful jobs 300% black density increasing

NO CAMERA NO DARKROOM NO AEROSOL

Reduce your film cost

Most economic film maker In the market.

SAVE LABOR

SAVE TIME

MAKE MORE MONEY

Just a laser print on a translucent paper or a transparent film, go through our LaserBlack enhancer, the print can be 300-400% darkened in black density (over 3.5). no matter it is a positive or neqative, This is good enough for any

kind of plate exposure, do not have to use image setter or photo film from a reproduction camera anymore. It is very simple and easy, everybody can do it. Even a most opaque density needed. The longest exposure time for a 7 mm thickness photopolymer plate can be exposing directly for corrugated board printing.

Positive – Negative Film output system

No camera No image setter No more photo-film Available Models : LB-A4 A3

◎ Suggest use HP / Canon Laser Printers for best results

◎ A Quick-Black gun and 500C.C. of LB-Solution will be equipped with every purchase of A3/A4 Enhancer

◎ One liter LB-Solution can process 2000 sheets of A4 size tracing paper / transparent film (with no evaporation)

◎ New Super-Black toner cartridge available now to achieve density over 3.5-4.0 its cheaper than a HP/Canon original

◎ It is as simple and easy as to operate a fax machine.

◎ Motors are UL/CE listed, all the parts are guaranteed.

◎ No air pollution not harmful to your health any more.

◎ LaserBlack is a non-toxic, friendly, green chemical.

◎ After operation, just clean your hands with water

◎ Just a laser print onto tracing paper from your P/C.

◎ Go throughout our LaserBlack you get a darkened film

◎ Opaque density can reach or over 3.50 (3 to 4 x darker)

◎ Same good results with fine line / character and dots.

◎ Good for all kinds of exposing during plate making.

◎ Excellent quality to match with your internet standard

◎ Save cost of camera, say good-bye to photo-films

◎ LaserBlack is a scientific method becoming a new trend

PC COMPOSING LSASER PRIT LASERBLACK ENHANCER PLATEMAKE

CE Certificate & Declaration of LaserBlack

We are very proud to announce that we have been approved & granted Certificate of Test No. R08022201E, Meantime CE Declaration of Conformity is also available for all the EU dealers and clients from us under your request.

Re: C-2430ET/WD

I am delighted to report that the equipment works well. I made some excellent TOREFLEX plates yesterday using the C-2430ET/WD. I will have no trouble selling it. In fact, I plan to sell it next week to a customer in Melbourne. He is coming to inspect it tomorrow (or Monday at latest).

BEN CASTLEDINE

Product Manager - Consumables

_______________________________

GMS (Graphic Machinery & Supplies)

Australia

LaserBlack - Introduced at the 2002 SGIA show. We have no experience

with this product, however it appears to make the images on both our

Translucency and LaserFilm the most opaque we have ever observed.

We are very anxious to receive customer reports on this product.

Mike - I followed your link to the Laser Black site and got in touch with Tony Chu their rep in Los Angeles. He came down to San Diego to show me the system and I bought one. Really something else! I make positives for sikscreening and used to use Laser Buddy but the laser Black system puts that to shame. Not only does it make the image twice as dense but it also fills gaps in the toner. It is a bit more work but in the long run well worth it for a real quality positive. I sell a lot of film to printers in the area and they're all really stoked with the results as well. If not for your link I'd have never known about this. Thanks and Good Luck. - JM

James M. Madden

7431 Cuvier Street

La Jolla, CA 92036-5005I have been using Tony Chu's excelent Photopolymer wash solution when he introduced the Laser Black for making our negatives in house,I must say that not only it worked well, it reduced our cost of negs drastically and gave us much more flexibility in serving our customers. I highly recommand it.

Kazem Rezvani

V.P.Operation

Pacific Western Sales

Ever Great Screen Process

Films needed for screen printing supposed to be not necessary in a high end quality, however, reproduction by camera and developing in the dark room to make film for plate making is not a good way for our mass production jobs as well as too much time consuming. And most of all we can not afford the high cost to have film made by an image setter.

For these reasons, we have tried very hard to find a way to get the image from our monitor to have a final solution of getting a film for our plate making just from a printer, so we have tried all laser and inkjet printers, unfortunately the black opaque is not enough at all. We also tried to get a black print from color laser printer (which cost us lot of money) in order to get more density but still failed.

Until we find and use the LaserBlack Enhancer, now we only use our HP Laserjet printer to print on tracing paper / film then go through the Enhancer the density go up 300% immediately after drying. For the fine image and small dot the reproduction is as good as it is made by a camera or a setter. In the high peak season, we can make 1000 sheets A3 size enhancement in a working day. LaserBlack Enhancer is a important economic high efficient tool for us now.

You may not know that this is also a secret where our profit comes from!

Taipei / TuChen / Chen Min-Yo

EnChee Label printing

Our company is a label stick printer located far away from center of city, when salesmen received orders, they deliver the original to the image setter service center then bring the film back for plate making the next day, it is very inconvenient to wait for a long time and need a courier to get the film back. In case of any mistake or problem then we have to wait for another day.

Since we have installed the LaserBlack Enhancer, we can have a negative film right from image on our monitor in few minutes and ready to make a photopolymer plate for printing within an hour. We don’t have to wait so long as in the past any longer and we have increased lot of our productivity due to the efficiency.

At the beginning, we doubted with the opaque density from the enhanced quality is really good enough as a negative film to expose photopolymer plate. Until we find that the system not only melt the toners in a very even layer as a coating on the paper / film, but also we find that gaps between toners and toners are all filled up. This is really a marvelous invention that have helped us so much in production!

Although we are still rely on image setter for high fine dot reproduction, but 80-90%

of the jobs are done by the LaserBlack Enhancer. We all love it very much!China / ShenZhen / The-Hon Cheng

GiFong corrugated plate process co.

We are based in Taiwan and start our plate making business for corrugated board printing since 1999, now we have 6 plants located in China. All of our plants are using LaserBlack Enhancer to make negative film for our photopolymer plate making, we appreciate to have this brand new invention to make film and heard of that they have been granted inventions and patents in 20 countries including USA, Germany, Japan…..etc.

We used to have a camera and darkroom in each plant to make negative film for a long time, while LaserBlack system is only using a HP Laserjet printer, at the beginning we all afraid of the opaque density will be not good enough for the longest 7mm thick photopolymer plate exposure, however, LaserBlack Enhancer has a Super Black Cartridge and proved the quality of 300% black density increase immediately after drying, now we have cleared more room for us by drawing away the camera and film processor by tearing down the darkroom completely.

We are using HP laserjet printer to print the image on tracing paper / transparent film

and go through the LaserBlack Enhancer to get the high black density negative film to expose the photopolymer plate directly, this save us much of time, labor, cost and get very good efficiency, during this high price competition to have more productivity and cost saving are really very important for managements.Only very few times for the gradation back ground or the color separation jobs, we have to rely on an image setter service center. Actually over 90% of the films are made by LaserBlack Enhancing System, now we have 6 units of LB-A3 enhancers used in our factories satisfactorily.

China / QunSan / John Chang