CTP Digital image on flexo plate

CTP Digital image on flexo plate CTP laser for color label

CTP laser for color label CTF Digital inkjet film making

CTF Digital inkjet film making CTF 175 / 133 / 85 lpi dot

CTF 175 / 133 / 85 lpi dot CTS digital image on screen

CTS digital image on screen LaserBlack- black film enhancer

LaserBlack- black film enhancer @flexo liquid plate making

@flexo liquid plate making @flexo plate making machine

@flexo plate making machine Model: EZ (Easy type)

Model: EZ (Easy type) Model:A4/A3/A2

Model:A4/A3/A2 2436/3040/4050/4260

2436/3040/4050/4260 New automatic washout m/c

New automatic washout m/c Clean & wash after printing

Clean & wash after printing Stamp Making

Stamp Making Photopolymer plates

Photopolymer plates Letterpress plates

Letterpress plates Flexo plates (solvent wash)

Flexo plates (solvent wash) Water wash flexo plates

Water wash flexo plates Digital photopolymer plates

Digital photopolymer plates Liquid photopolymer resins

Liquid photopolymer resins For cup.can.tube.pad printing

For cup.can.tube.pad printing For block print

For block print Cushion Backs = F-Bak

Cushion Backs = F-Bak Double-side tapes for printing

Double-side tapes for printing In plant plate making

In plant plate making

View Big Picture

View Big Picture

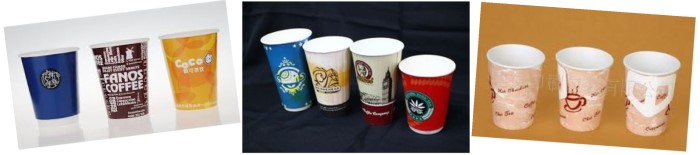

For CUP printing

Innovative photopolymer plate

For color paper cup / plastic cup best plates

All new formula KM-73, KM-83 longer endurance

A BRAND NEW CONTRIBUTION FOR

Good for color cup, can and tubes

QUALITY AS GOOD AS DIGITAL PLATE

no film, no digi plate with 175 LPI sharp dots on your plates

NO HEAVEY CAPITAL INVESTMENT

No more digital plates for CTP plate making?

Prepress innovation after reaching perfect resolution of 175 lpi 1% reproduction for all printing plate making by CTF (Computer To Film) inkjet images on special coated films, now same results to print direct on letterpress and flexographic plates for fine color flexible packaging, label and box printing is available now. This is due to new breaking through of nozzle technology with a flatbed printer able to print fine images on plate materials directly which means that no expensive digital plate and laser equipment are required for CTP (Computer To Plate) in printing industry any more.

To apply a black layer with an enough opaque black density on plate then use laser technology for fine image ablation in order for go through the UV light to cue the area for printing, this is the principle of a digital plate. First of all it is necessary for a machine to apply laser beam although it is not strong but still more expensive than an inkjet printer. Secondly, the plate needs to have a black layer coating which means the cost is increased and not all plates are available with this coating for some users.

Meantime because of fine reproduction is now possible, this is also a good news for screen printers especially for fine electronic circuit industry (PCB), CTS (Computer To Screen) will be an ideal choice of reproduction the plate without film, vacuum and exposure, these functions now are all can be done at the same time by equipping together with a LED/UV lamp inline the printer for sharper image, less labor, time saving and reducing wastes due to failures during the process.

For CAN printing

Good reproduction with more fine details for 2-piece can

More impressions for successful production

Water washout quality is much better than alcohol plate, non flammable and no drain problem.

For TUBE printing

good for color plastic and metal tube printing

Water washout best quality. Adapted by most of the tube printers in the world.

PAD plate-for Tampo printing

Environmental green & healthy impression from 1000 – 10000 depends on the following printing conditions :

(some time can reach 1 million copies)

A. Kinds of ink is using

B. What image designed

C. Use quick-dry up inks

Film based plate is easy to cut off and with beautiful edges steel base with stable surface and for

good registration features of PAD photopolymer :

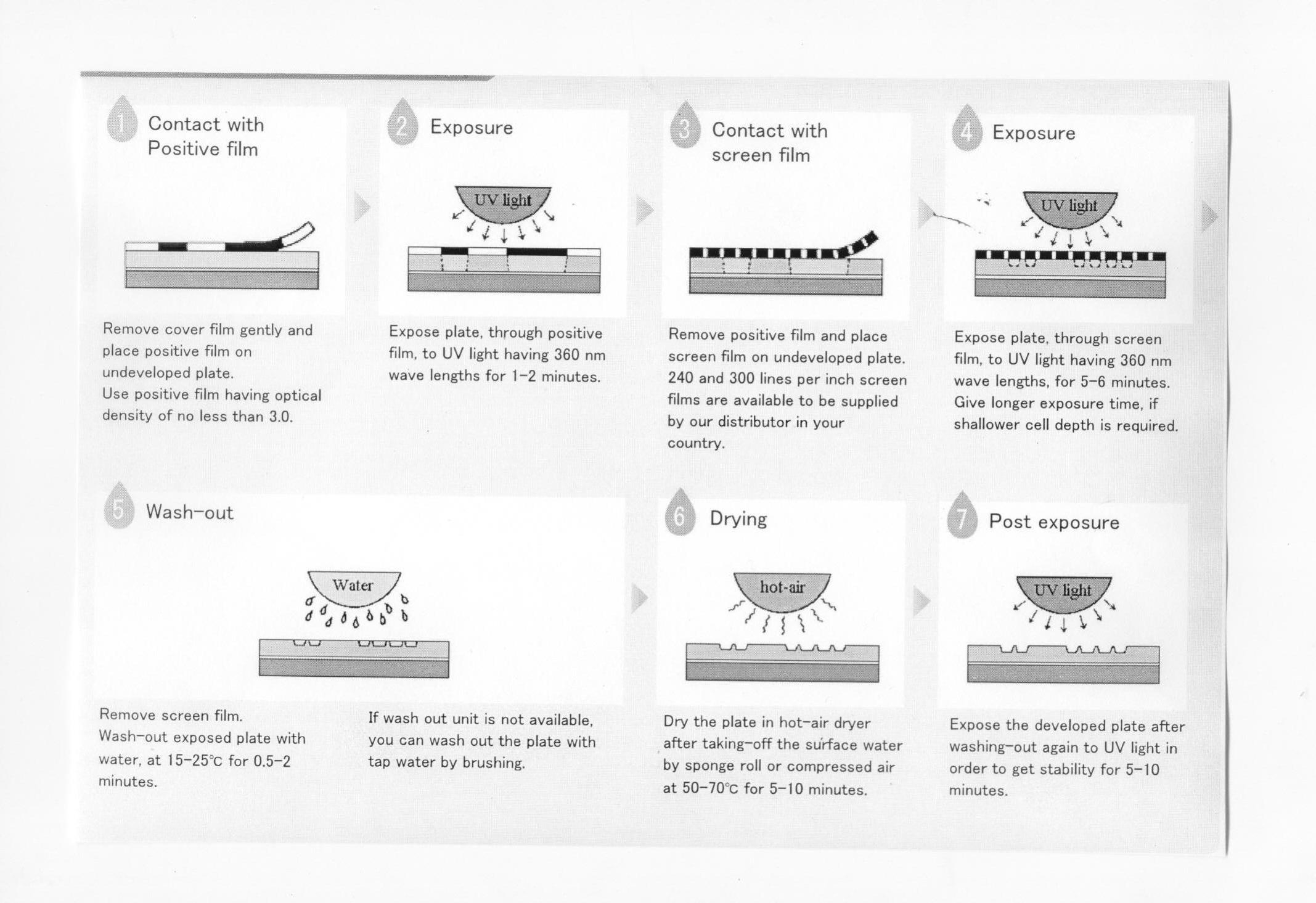

Easy process : No etching, simple and easy to make in house, ready to print quickly.

Water washout : Do not have to use solvent and toxic chemical just use water to wash.

High reproduction : Able to print fine dots and lines by using 95% 300 1pi screen film.

More impression : Excellent durability because of highly close-linked polymerization